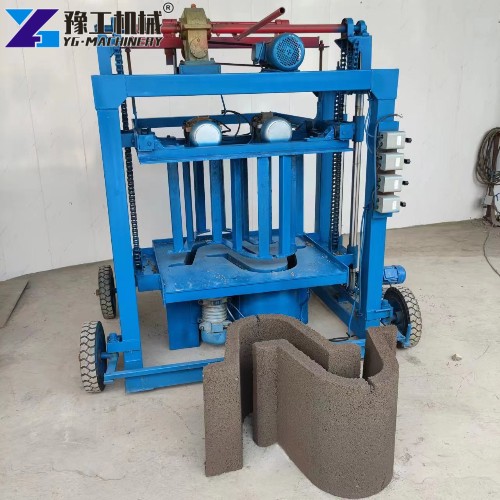

Do you want to know how to make bricks quickly? The secret is using a block brick machine! This is a special machine that helps you easily make all kinds of bricks. It uses common materials like slag, mine waste, fly ash, stone powder, sand, gravel, and cement. Mix these materials in the right proportions, add some water, stir them, and then use the machine’s strong pressure. This will press out strong cement bricks, hollow blocks, or beautiful colored paving bricks. This equipment is also known as a “non-fired brick machine.” This means the cement bricks or hollow blocks produced do not need to be fired. They can be shipped out after a short period of drying. Sounds convenient, doesn’t it?

Block Brick Machine Production Capacity

| Block Name | Size (L*W*H)mm | Molding Cycle | QTY/Mould | QTY/hour | Qty/8hr |

| Hollow block | 400*200*200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520pcs |

| Hollow block | 400*150*200 | 15-20s | 7pcs | 1260-1680pcs | 10080-13440pcs |

| Hollow block | 400*100*200 | 15-20s | 11pcs | 1980-3640pcs | 15840-21120pcs |

| Porous block | 240*115*90 | 15-20s | 15pcs | 2700-3600pcs | 21600-28800pcs |

| Standard brick | 240*115*53 | 15-17s | 30pcs | 6300-7200pcs | 50400-57600pcs |

| Paver | 225*112.5*60 | 20-25s | 15pcs | 2160-2700pcs | 17280-21600pcs |

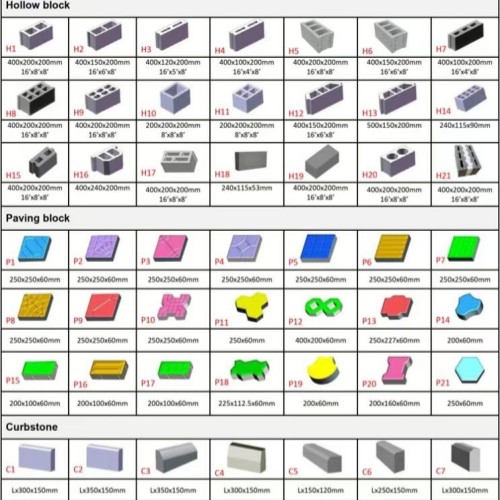

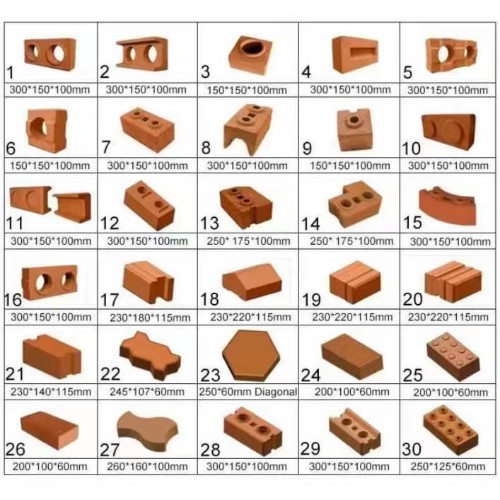

Customize Your Brick Molds

Our block brick machine is very flexible, allowing you to customize brick molds of different shapes and sizes. Whether you need standard bricks, special-shaped bricks, or paving bricks of various colors, we can help you achieve it. This adds diversity to your products, meeting the needs of different customers.

Different Types of Block Brick Machine

Based on the molding principle, brick machines are mainly divided into three types:

- Vibration molding: Uses high-frequency vibration to compact and form the material.

- Hydraulic molding: Uses the powerful pressure of a hydraulic system to press bricks.

- Hydraulic and vibration combined: Combines both vibration and hydraulic methods for higher efficiency.

In addition, brick machines are also divided into automatic and semi-automatic types. Automatic machines are smarter and easier to operate; semi-automatic machines require some manual operation. You can choose the type that best suits your needs.

Choose the Right Brick Machine Based on Raw Materials

- Vacuum extruder brick machine: Mainly used for producing clay bricks.

- Clay brick machine: Specifically handles clay materials. If you need a clay brick machine, we can offer various models.

- Cement brick machine: Suitable for making bricks using cement and other aggregates.

Block Brick Machine Q&A

Standard configuration is electric, diesel generator can be added

Elena can be contacted via WhatsApp to send you a product video.

Semi-automatic machine vibration molding, fully automatic machine hydraulic molding

Customer Reviews

“I used YG’s brick machine, and it’s really great! It’s easy to operate and very efficient. My brick factory’s output has doubled now, thank you so much!”

— John from the USA

“Before, we were always worried about production efficiency. Since we started using YG’s brick machine, all our problems are solved. The brick quality is excellent, and our customers are very satisfied. Highly recommended!”

— Anna from Russia

Brick Making Machine – YG Machinery Manufacturer

The block brick machine we sell can produce standard bricks, hollow bricks, interlocking bricks, perforated bricks, solid bricks, sand bricks, etc. Of course, we have other construction machinery, hydroseeding machines, fog cannon machines, dust control water trucks, sandblasting machines, stucco machines, putty spraying machines, cement forming machines, concrete mixer machines with pumps, micro excavators, GRC machines, house sheds, etc. Contact us immediately to learn more and get a price quote.