Maintenance tasks for urban and industrial pipelines are challenging. Traditional manual cleaning is dangerous and also highly inefficient. Now, the sewer cleaning robot changes this situation. These robots access confined and highly corrosive environments. They execute cleaning work, ensuring clear pipelines. Therefore, adopting robotics is essential for modern maintenance. We understand that safety is the top priority, and efficiency is also crucial.

Sewer Cleaning Robot Parameter:

| Dimension: | 1220*890*520mm | Speed: | 2.5-4KM/h |

| Self Weight: | 120kg | Designed Load: | 100-300kg |

| Waterproof: | IP68 | Rated Torque: | 100-500 NM |

| Track Width: | 130mm | Reducer Efficiency: | 65-85% |

| Gear Ratio: | 1:10-1:40 | Motor Voltage: | 380ACV (customized as local voltage) |

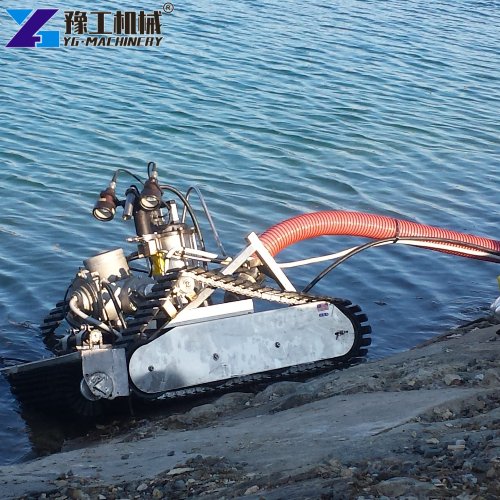

| Motor: | 0.75-1.5KW*2 | Climbing Ability: | ≤30°(can climb stairs) |

| Motor Rated Speed: | 1500r/min | Maximum Span: | 620mm |

| Cable Control Distance: | Standard 50m, maximum 150m | Over-Obstacle Capacity: | 130mm |

| Maximum Underwater Depth: | 30m | Power Supply: | Generator or 380V power supply |

Our sewer cleaning robot utilizes the advanced hydraulic dredging principle. As a 220V electric dredger, it delivers stable and eco-friendly power. Its core advantage lies in powerful suction and transport capability. The robot features an impressive $200m^3/h$ Production Capacity. Meanwhile, the Slurry Pump Lift reaches $15m$. Thus, our robotic dredge ensures maximum production rate.

Technical Advantages: Modular, Stable, and Anti-Corrosion

The design of the sewer cleaning robot focuses on long-term reliability. All machines feature modular robot design, easing transport and setup. The robot is equipped with a robust crawler drive system. This guarantees stable movement on muddy or uneven surfaces. Additionally, we use anti-corrosion materials. This helps it resist the chemical corrosion of wastewater, ensuring continuous operation.

Application Scenario One: Municipal Pipeline Inspection and Cleaning

In the municipal sector, our sewer cleaning robot plays a key role. It integrates pipeline inspection and cleaning robot functions. The robot uses underwater navigation sensors for precise obstacle avoidance. Its dredging width reaches $1250mm$. Furthermore, it efficiently cleans pipelines at a $3-9m/min$ travel speed. This integrated technology enhances maintenance efficiency and operational safety.

Application Scenario Two: Industrial Ponds and Sludge Cleaning

The technology of the sewer cleaning robot is flexible. Our sludge cleaning robot can be used for industrial pond dredging. For instance, cleaning sedimentation basins in petrochemical plants or ash ponds in power facilities. These machines precisely remove high-concentration sludge. They replace hazardous manual cleaning methods. Therefore, they significantly boost the operational safety of industrial companies.

Industry Case Study: Efficient Completion of Major Dredging Projects

One of our clients used our dredging robot to clean a large reservoir. They chose our mini dredging machine because it achieves high-precision lake sediment removal. The robot’s efficient $200m^3/h$ production capability ensured the project finished on time. Furthermore, the 1-Year Warranty Robot we provide, along with comprehensive technical support, gave the client confidence in their ROI.

Choose YG Machinery: Your Trusted Sewer Cleaning Robot Supplier

Selecting the correct equipment is vital. YG Machinery specialises in providing reliable sewer cleaning robot solutions. Our product specifications and modular design prove our technological advantage. We offer comprehensive technical support and high-quality products. Are you ready to upgrade your pipeline maintenance? Contact us today for a free quote and speak with our expert team!