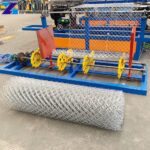

Tired of low efficiency and high costs from manual chain link weaving? Looking for a durable machine that fits multiple specifications? YG Machinery’s chain link machine solves these problems. It automates wire feeding, forming, and weaving, cutting labor costs while improving product consistency. It’s a top choice for municipal, agricultural, and warehousing industries.

Chain Link Machine Parameter:

| Model | YG-20-100 | YG-25-80 |

| Wire diameter | 1.3-4mm | 2-4mm |

| Mesh size | 20-100mm | 25-100mm |

| Mesh width | 0.5-4m | 0.5-4m |

| Speed | 70-80m²/h | 120-180m²/h |

| Mesh length | 30m, adjustable freely as promised | |

| Mesh side | Knuckled and twisted, or knuckle, or twisted | |

| Raw material | Galvanized wire, PVC-coated wire, etc. | |

| Machine size | 4.2*2.2*1.7m | 6.7*1.43*1.8m |

| Weight | 2000kg | 4200kg |

| We can design the machine according to your wire diameter, mesh hole size, mesh width, and voltage. | ||

Chain Link Machine: Core Features & Technical Advantages

How Does the Chain Link Fencing Machine Work?

The wire mesh welding machine process is easy to understand: First, metal wire enters the feeding system. After straightening, the forming module bends the wire into links. Then the weaving unit connects links into a full mesh. Finally, it cuts the mesh to your set length. No manual intervention is needed—from raw wire to finished mesh, it’s one-step.

Core Advantages of Chain Link Machine

- High Automation: Equipped with an intelligent control system, it sets speed and mesh size automatically;

- Wide Adaptability: Supports 2mm-6mm wire diameters and 1m-3m wide meshes, matching chain link fence machine production needs;

- Strong Stability: Key parts use high-strength steel, with low noise and failure rates (below industry average), reducing downtime;

- Energy Saving: Optimized motor design cuts energy use by 15% vs. similar machines, saving money long-term;

- Easy Operation & Maintenance: Simple interface—new users learn in 1 hour. Wear parts are easy to replace, and it works with [automatic fencing machine] for assembly lines.

4 Common FAQs About Chain Link Machine

Regular wire mesh welding machine produces 100-150㎡ per hour; high-end models reach 200㎡/h. Speed depends on wire diameter and mesh size—we’ll recommend the right model for you.

Absolutely. We offer 24/7 online technical support—engineers respond within 1 hour if issues arise. Common parts are in stock and available for purchase on demand. We also provide equipment maintenance guidance to help extend the service life of your wire mesh welding machine.

Application Scenarios & Success Stories of Chain Link Machine

Key Application Areas of chain link fencing machine

- Municipal Construction: Makes road barriers and park fences. Chain link machine mesh is corrosion-resistant and impact-resistant, lasting over 10 years;

- Agriculture & Animal Husbandry: Produces farm fences and livestock enclosures. Pair with the wire mesh welding machine for sale accessories to speed up installation;

- Warehousing & Logistics: Creates shelf dividers and warehouse partitions. Chain link wire mesh making machine mesh bears weight, preventing cargo drops;

- Sports Venues: Makes basketball/football court fences. Uniform mesh holes and good elasticity meet safety standards.

Success Story: Mike’s Production Upgrade in Australia

Mike, an Australian fence installer, used manual weaving until 2023. He made only 30㎡ daily with 3 workers—costs were high. We recommended a medium wire mesh welding machine and adjusted parameters for local wire specs.

After installation, Mike’s daily output jumped to 90㎡ with 1 worker. He saved ~4,000 AUD/month in labor costs. In early 2024, he ordered another chain link fence machine for sale to expand into agricultural fencing. Now his business covers 3 eastern Australian states, with 35% monthly profit growth. “YG’s machine is efficient, and after-sales response is timely,” Mike said. “No production delays at all.”

YG Machinery: Your Trusted Chain Link Machine Supplier

Our Service Guarantees

- Pre-Sales Consultation: Custom wire mesh welding machine solutions based on your output and specs;

- Custom Production: Support special specs (e.g., adding auto mesh winding, adapting to special wire materials);

- After-Sales Support: 24/7 hotline, equipment maintenance guidance, and supply of common parts;

- Technical Materials: Provide detailed operation manuals and maintenance guides for quick startup.

Customer Testimonials

John (USA): “I’ve used YG’s wire mesh welding machine for nearly 2 years—no major faults. Engineers fix small issues remotely. It’s more cost-effective than my old European machine.”Sarah (South Africa): “We paired YG’s automatic wire mesh welding machine with chain link machine for integrated production. Order delivery time is cut by half, and customer satisfaction is up.”

Get Free Wire Mesh Welding Machine Quote Now

Want to know the right wire mesh welding machine model and price? Need detailed tech specs? Click the button below to fill out the form—our engineers will contact you within 24 hours with a free quote and custom plan.