YG’s underground horizontal boring machine is a trenchless solution designed to install pipelines and cables underground without open excavation. Equipped with a fully integrated self-loading unit, closed-loop energy-saving circuits, electro-hydraulic proportional control, and load-sensing technology, it is widely used in water supply, power, natural gas, coal gas, and oil pipeline installations, offering contractors a highly efficient and reliable directional drilling solution. As a superior directional drilling machine for sale, YG’s HDD machine installs pipelines and cables without disturbing the surface. Unlike traditional open-cut methods, it preserves roads and landscapes, minimizing traffic disruption and ecological damage. Ideal for water pipelines, gas lines, power cables, and oil conduits. Particularly effective in municipal infrastructure projects, urban redevelopment, and energy transmission pipelines. Built-in HDD intelligent assistance system allows precise settings for bore depth, entry and exit locations, and pipeline bending radius. On-site adjustments ensure safety and drilling accuracy.

Underground Horizontal Boring Machine Parameter

| Model | YG100A | YG130A | YG160A | YG200A |

| Drilling Depth | 100M | 130M | 160M | 200M |

| Max Drilling Diameter | 400mm | 600mm | 750mm | 900mm |

| Power | 55Kw | 93Kw | 100Kw | 113kw |

| Engine | Diesel | |||

| Weight | 2700Kg | 3650Kg | 4750Kg | 8200Kg |

| Dimension | 3800*1600*1800mm | 4200*1650*1980mm | 4650*1670*2040mm | 6750*2050*2400mm |

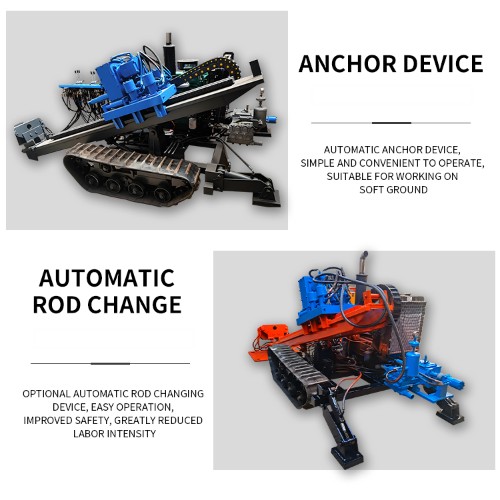

Small HDD (small directional boring machine): Utilizes double-buoyancy technology on the clamp and drive head, along with a high-low speed push-pull rotation system. It enhances drill rod adaptability and boosts operational efficiency. Perfect for smaller-diameter pipeline projects and can be paired with hdd drilling machine for sale solutions.

Large HDD: Features digital instrumentation, dual-power systems, and electronic sensing technologies for enhanced thrust and stability. Suitable for large-diameter, long-distance pipeline projects such as interstate oil or natural gas transmission lines.

Advantages of Underground Horizontal Boring Machine

- Minimal environmental impact: prevents large-scale excavation, preserving urban landscapes; reduces soil erosion and protects sensitive ecosystems.

- Significant cost savings: lower restoration costs—no extensive backfilling or landscaping required; reduced labor demands—shorter project timelines lower man-hour expenses; faster completion—accelerates project schedule and roi compared to open-cut methods.

- High versatility and adaptability:operates effectively in challenging terrains including rocky soil, wetlands, and crowded urban areas; supports heavy-duty operations within the hdd machine100 ton price range, ensuring seamless installation of high-load pipelines; small hdd models can work in tandem with small directional boring machine for auxiliary branch installations.

- Advanced control technologies:closed-loop hydraulic circuits and electro-hydraulic proportional control optimize energy use and reduce emissions;load-sensing control monitors drilling resistance in real time, ensuring stable operation in complex geological conditions; intelligent assistance system continuously gathers underground data to minimize project risks and improve safety.

Global Customer Success Stories

Client Feedback One: From India

“YG’s underground horizontal boring machine precise control and robust performance allowed us to complete the water pipeline installation in a densely populated urban corridor ahead of schedule and significantly under budget. The minimal surface disruption was a huge advantage, saving us considerable restoration costs and public relations challenges. We were particularly impressed with its adaptability to varied ground conditions.”

Client Feedback Two: From the United States

“For our critical gas line project, safety and precision were paramount. YG’s large-scale underground horizontal boring machine delivered exceptional performance. The dual power system provided the reliability we needed for a challenging river crossing, and the electronic sensing technology ensured our operations were both accurate and secure. ”

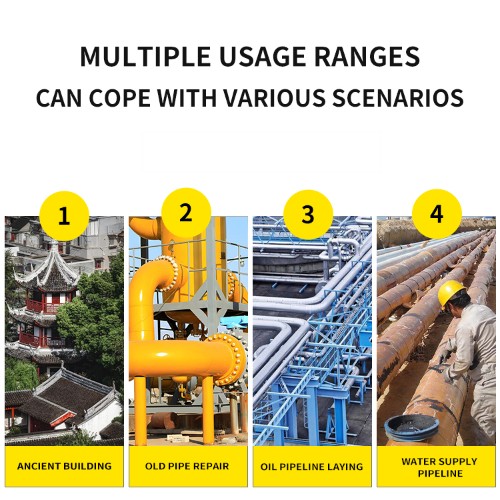

Application Scenarios and Scope

- Municipal infrastructure: urban water supply and drainage pipeline retrofits; natural gas, oil, and coal gas pipeline installations; underground power cable and communication fiber-optic deployments.

- Energy transmission projects: long-distance, cross-region gas and oil pipeline installations; petrochemical facility pipeline construction.

- Industrial parks and factories: industrial pipeline retrofitting and underground cable installations; infrastructure upgrades within manufacturing complexes.

- Rural and agricultural areas: irrigation pipeline installations for farmland; rural water supply and wastewater treatment pipeline projects.

- Challenging geological conditions: rock layer or wetland crossings beneath highways or waterways; mountainous terrain pipeline placements.

Underground Horizontal Boring Machine – YG Machinery Manufacturer

YG Machinery is dedicated to developing and manufacturing high-quality, high-performance drilling equipment, backed by years of expertise in geotechnical engineering machinery. Our production team adheres to strict international quality management standards, and our products are trusted by clients worldwide across various industries. If you need detailed information, please contact YG Machinery directly, specifying your exact requirements and budget. Our professional team will provide you with the most accurate quotation and the best procurement scheme. Additionally, YG offers a variety of drilling rigs, including water well drilling machines, diamond core rigs, and rotary drilling rigs.