In today’s market, manual rebar processing is history. If you want to boost site productivity, a reliable steel bar straightening and cutting machine is a must-have. It pulls coiled wire, straightens it, and cuts it to exact lengths. This automation significantly reduces material waste.

Actually, the right setup can save you thousands in labor costs annually. It’s not just about speed; it’s about precision.

Tip: Before buying, always check the roller material. A quality bar straightening machine should use hardened alloy steel to ensure a longer service life.

Core Specs Comparison: How to Choose?

Different projects require a different rebar straightening machine. Choosing the wrong power rating will lead to motor burnout.

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire Length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

If you focus on small residential builds, a standard rebar straightening machine works fine. However, for bridge construction, you need the heavy-duty version with hardened alloy rollers.

Why Choose Our Steel Bar Straightening and Cutting Machine?

Most standard machines slip when handling high-strength rebar. Our equipment uses a high-performance hydraulic cutting system. This means the cutting process is smoother with much less noise.

- High Precision: Length error is kept within ±5mm.

- High-Speed Operation: Processing speeds reach 30-45 meters per minute.

- Smart Control: Equipped with numerical control (CNC) for easy “plug and play” operation.

Wide Application Scenarios of Steel Bar Straightening and Cutting Machine

Tip: Different industries have different requirements for equipment parameters; bridge projects need to focus on large-diameter processing capacity

1. Transportation Infrastructure Field

In expressway, high-speed railway, and bridge projects, the steel bar straightening and cutting machine is used to process load-bearing rebar for pile foundations and beam bodies. Its efficient processing capacity can meet the concentrated rebar demand of large-scale projects and ensure construction progress.

2. Construction Engineering Field

In the construction of residential buildings, commercial complexes, and other buildings, the equipment can process various materials such as grade Ⅲ steel, hot-rolled round steel, deformed steel bar, and cold-rolled rebar with diameters of 4-16mm, adapting to the rebar processing needs of different parts such as floor slabs, beams, and columns.

3. Special Engineering Field

In projects with high requirements for rebar precision such as nuclear power plants and port terminals, the high-precision straightening and cutting functions of the steel bar straightening and cutting machine can meet strict construction standards and ensure project safety.

Real Customer Case: How Does the Steel Bar Straightening and Cutting Machine Create Value?

Customer Peter from Australia, whose construction team once faced problems of low rebar processing efficiency and excessive waste, saw significant improvements after using the steel bar straightening and cutting machine from YG Machinery:

- Processing efficiency increased by 38%: From 8 tons of rebar processed per day to 11 tons;

- Waste rate reduced by 22%: Saving about 3,000 Australian dollars in steel costs per month;

- Labor costs decreased by 15%: The equipment operates automatically without the need for special personnel to monitor and debug.

Peter said: “The PLC control system of the equipment is very easy to use. Workers only need to input parameters to run automatically, and the precision is far higher than manual operation.” In addition, another bar straightening machine helped customers shorten the construction period by 10% in a European road reconstruction project.

Frequently Asked Questions (Q&A)

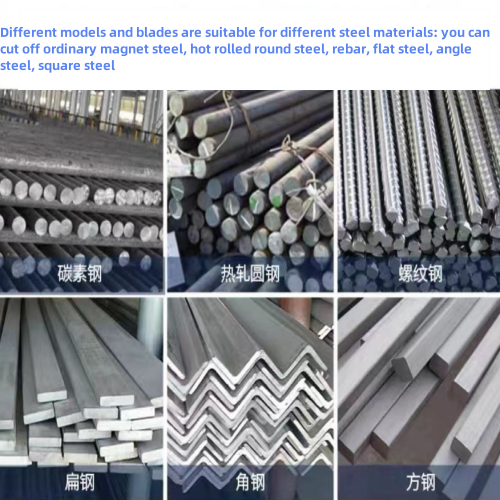

Yes. The equipment is suitable for various materials such as plain carbon steel, hot-rolled round steel, deformed steel bar, and cold-rolled rebar. Corresponding blades can be replaced to process profiles such as flat steel and angle steel.

No, it’s not. Regularly lubricate moving parts, clean the equipment surface, and check the tightness of bolts. Wearing parts are easy to replace without professional technicians.

Yes. Our machines are designed for both smooth round bars and deformed (ribbed) rebar.

Mainly the straightening wheels and the cutting blades. We suggest buying one extra set with the machine.

Not at all. We test the machine before shipping. You only need to connect the power and add hydraulic oil.

Would you like me to send you a detailed quotation and the latest technical catalog for our steel bar straightening and cutting machine?