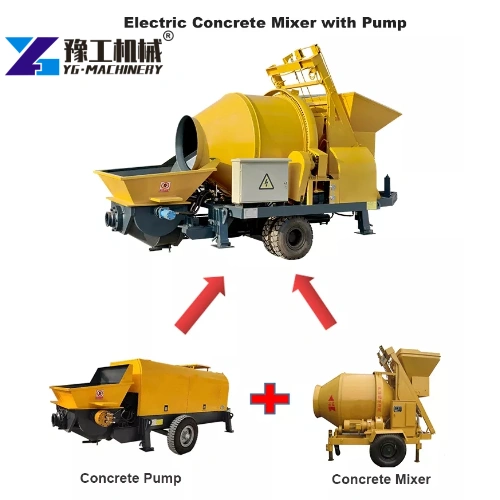

In the global construction industry, time and efficiency determine project success. YG Machinery’s pump mixer concrete combines concrete mixing and pumping into one compact unit. It’s the ideal solution for contractors who need to save labor, improve productivity, and ensure consistent concrete delivery. From residential housing to bridge and road projects, this machine has earned the trust of customers worldwide.

Product Analysis and Technical Advantages

| Technical parameters | ||

| Maximum Theoretical Concrete Mixing | M³/h | 15 |

| Maximum Theoretical Concrete Output | M³/h | 30 or 40 |

| Theoretical maximum transmission distance | m | Vertical 50/Horizontal 200 |

| Distribution Valve Form | S valve | |

| Hopper Volume*Height | L*mm | 600×1080 |

| Pumping Motor Power | KW | 30 or 45 |

| Winch Motor Power | KW | 5.5 |

| Hydraulic Oil Form | open circuit | |

| Rated Speed | rpm | 1480 |

| Fuel Tank Capacity | L | 170 |

| Weight | kgs | 3500 |

| Concrete Delivery Pressure | Mpa | 6 |

| Concrete Cylinder Specification*Stroke | mm | φ180 * 800 or 200 * 800 |

| Spout Diameter | mm | φ180 |

| Mixing Motor Power | KW | 8 or 4 |

| Pump Motor Power | W | 550 |

| Maximum Aggregate Size | mm | Grait:40MM; Gravel:30MM |

| Voltage | V | 380 |

| Dimensions (L * W * H) | mm | 4200x2100x3300 |

Product Structure and Working Principle

The pump mixer concrete integrates a mixer drum and a concrete pump system in one frame. Once materials are fed into the drum, the hydraulic system automatically mixes and pumps concrete to the target point. This compact design saves space, simplifies operation, and is perfect for on-site jobs.

YG Machinery offers several options, such as a small concrete mixer pump, a small concrete mixer with pump, and a concrete pump with mixer machine, giving flexibility for various construction needs.

Core Advantages

- High efficiency: Mix and pump at the same time, saving construction time.

- Labour-saving: Reduce manual work by 2–3 workers.

- Stable output: The advanced hydraulic system ensures smooth concrete flow.

- Easy to move: Compact and trailer-type design fits all terrains.

- Low maintenance: Key parts are made of wear-resistant alloy for a longer service life.

Pump Mixer Concrete FAQ

Yes. It performs both functions, which reduces equipment investment and transport costs.

We provide both diesel and electric models to meet different job site conditions.

Compared to separate machines, a concrete mixer and pumping machine combine two processes in one step. This reduces fuel, labour, and maintenance costs significantly. For small and medium-sized contractors, it provides a practical, cost-effective solution without compromising quality.

Applications and Real Customer Success Case

Applications:

- Residential building construction

- Village housing and rural road paving

- Bridge and tunnel concrete pouring

- Water conservancy and port engineering

Case Study – Philippines

A customer named Carlos from the Philippines used YG Machinery’s pump mixer concrete for a mountain highway project. The equipment solved his problem of difficult material transport and long concreting cycles. With this unit, his concrete output increased by 40%, helping him complete the project ahead of schedule. He commented: “This is a truly reliable machine with great performance.”

YG Machinery Strength and Service Assurance

With over ten years of experience in concrete machinery manufacturing, YG Machinery has exported products to more than 60 countries worldwide. We provide:

- Free technical consultation before purchase

- Customized concrete pumping solutions

- Full after-sales support and original spare parts supply

Customer feedback highlights:

“YG Machinery’s team responded quickly and professionally. Their service makes us feel confident using every piece of equipment.”

Looking for a smarter, more efficient concrete solution?

👉 Contact YG Machinery today to get your free quote for pump mixer concrete!

Our sales engineers are ready to provide detailed specifications and help you customise the perfect solution for your project.