Cleaning small molds and precision parts is always a headache: traditional methods are inefficient and may damage the workpieces. The mini dry ice blaster is here, bringing a new solution with its unique dry ice cleaning technology, making cleaning fast and safe. Compared with traditional sandblasters and laser cleaning machines, it has more advantages in small scenarios, and is even more flexible than shot blasting machines.

Mini Dry Ice Blaster Parameter:

| Model | ICE-JET 3.0 | ICE-JET 6.0 | ICE-JET 15 | ICE-JET 40 |

| Dry Ice Capacity | 3KG | 6KG | 15KG | 40KG |

| Dry lce Consumption | 20-50KG/H | 20-50KG/H | 30-100KG/H | 30-100KG/H |

| Supply Pressure | 3-10bar | 13-10bar | 3-10bar | 3-10bar |

| Air Consumption | 1-2m³/min | 1-3m³/min | 1-4m³/min | 1-5m³/min |

| Weight | 40KG | 50KG | 65KG | 80KG |

| Dimensions | 460x340x750mm | 460x350x850mm | 550x445x985mm | 650x550x1000mm |

| Total Power | <500W | <800W | <800W | <800W |

Mini Dry Ice Blaster: Working Principle and Core Features

The working principle of the mini dry ice blaster is clever. When dry ice pellets at -78 degrees Celsius come into contact with the dirty surface, they cause embrittlement and explosion, making the dirt shrink and loosen. Then the dry ice pellets instantly vaporize and expand 800 times, generating a strong stripping force to completely remove the dirt.

Its core features are remarkable. It is small in size, convenient for operation in narrow spaces. The cleaning process is water-free and liquid-free, without causing secondary pollution. Moreover, it has a wide range of applications, capable of cleaning various items such as industrial molds, electronic components, and auto parts.

Three Core Advantages of Mini Dry Ice Blaster

Significant efficiency improvement: Compared with traditional cleaning methods, the mini dry ice blaster cleans 30% faster. It can quickly handle dirt, reduce equipment downtime, and improve production efficiency.

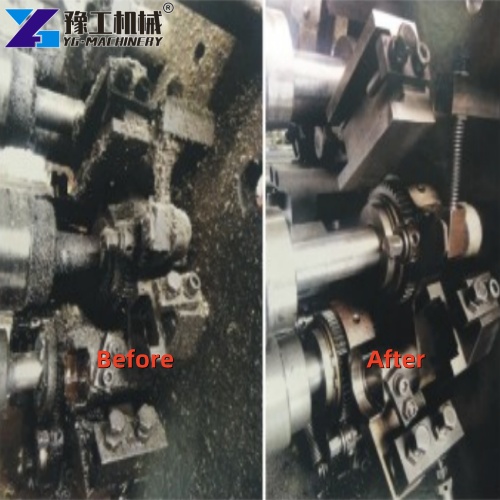

Reliable quality assurance: It adopts low-temperature cleaning, which will not damage the surface of the workpiece. After cleaning, the workpiece is as bright as new, without affecting its precision and performance, and prolongs the service life of the equipment.

Outstanding cost-effectiveness: In long-term use, it can reduce a lot of costs. There is no need for a large amount of cleaning agents, reducing consumable expenses. At the same time, efficient cleaning reduces labor input, making the dry ice cleaning machine cost more advantageous.

Common Questions About Mini Dry Ice Blaster

It is suitable for small factory workshops, laboratories, maintenance stations, etc. It is small in size, easy to move, and can operate flexibly in limited spaces.

No. The operation is simple. Can get started quickly as long as they master the basic steps and safety precautions. We will also provide an operation guide.

No. The equipment has a simple structure and few wearing parts. Doing regular inspections and cleaning at ordinary times can reduce failures and lower maintenance costs.

Application Scenarios and Success Cases of Portable Dry Ice Blasting Machine

Wide application scenarios: In the electronics industry, it can clean integrated circuit boards, etc.; in the automotive industry, it can remove engine carbon deposits, and the [dry ice car cleaning machine price] used here is also very competitive; in the food and pharmaceutical industries, it is used for equipment cleaning and disinfection, etc.

Success case: A customer in the United States, after using the [mini dry ice blaster] in auto parts production, increased cleaning efficiency by 40%, reduced the rejection rate by 15%, and shortened the delivery time by 3 days.

How to Choose the Suitable Model of Mini Dry Ice Blaster?

When choosing, consider the material of the cleaning object and the type of dirt. If it is a precision electronic component, choose a model with lower power; if cleaning auto parts with heavy oil stains, you can choose a model with slightly higher power. At the same time, combine your own site size and production capacity needs, and we will provide professional suggestions according to your situation. If you also want to know about the selection of sandblaster models, you can consult us at any time.

The Difference Between Portable Dry Ice Blasting Machine and Other Cleaning Equipment

Compared with sandblasters, mini dry ice blaster will not damage the surface of the workpiece; compared with laser cleaning machines, it has lower cost and is more suitable for small and medium-sized enterprises; compared with shot blasting machines, it is more flexible and can clean parts with complex shapes.

The Combined Use of Dry Ice Pelletizer and Mini Dry Ice Blaster

If there is no dry ice, our dry ice pelletizer can be useful. Small dry ice making machines can be used with mini dry ice blaster to ensure a stable supply of dry ice. For example, the T6 model is suitable for deburring in the 3C industry and mold industry. If you are interested in the combination of laser cleaning machines and dry ice pelletizers, we can also introduce them to you.

Strength and Service Guarantee of YG Company

YG Company has rich experience in the mechanical foreign trade field, focusing on product research and development and quality control. We provide pre-sales consultation to help you select suitable equipment; we can also provide customized solutions to meet special needs. The after-sales service is perfect, including technical support, spare parts supply and regular maintenance, so that you have no worries. Whether it is mini dry ice blaster or shot blasting machine, we can provide high-quality services.

A French customer commented: “YG’s mini dry ice blaster is very easy to use, the cleaning effect exceeds expectations, and the service is very considerate.”

Get the Exclusive Plan of Portable Dry Ice Blasting Machine Immediately

Our mini dry ice blaster has been sold to many countries such as the United States, Japan, and South Korea. Now, you can get a free quote immediately and customize an exclusive solution.

We look forward to your inquiry, and we will introduce you to more details of the product and related supporting equipment information!