In modern construction projects, precise rebar bending is essential. Traditional manual methods are inefficient and lack accuracy, significantly slowing down construction and increasing labor costs. To address these challenges, a high-performance hydraulic rebar bender is the ideal solution. As a professional construction machinery supplier, YG Machinery’s hydraulic rebar bender effortlessly handles complex rebar bending needs, offering an efficient, precise, and safe solution for your projects.

Hydraulic Rebar Bender Parameter:

| Model | YG-WG150 |

| Type | Hydraulic |

| Bending angle | 0-180° |

| Apply for the diameter of the steel pipe | 25-133mm |

| Power/Voltage | 11kw/380v 50hz |

| Main shaft rotary speed | 9r/min |

| Bending angle quantity | 9 |

| Applicable pipe thickness | ≤5mm |

| Machine size | 1900*2100*1400mm |

| Machine weight | 1500kg |

Parameters of CNC Pipe Bender:

| Model | YG-26 | YG-38 | YG-51 | YG-76 | YG-N76 |

| Tube diameterMaximum wall thickness | Φ8-26mm2mm | Φ10-38mm3mm | Φ10-51mm3mm | Φ10-76mm3mm | Φ10-76mm4-5mm |

| Maximum square tube diameterMaximum wall thickness | 25mm2mm | 30mm3mm | 40mm3mm | 50mm3mm | 60mm3mm |

| Maximum rectangular tube diameter(Vertical Bend) Maximum wall thickness | 10*20mm2mm | 20*40mm3mm | 30*50mm3mm | 40*80mm3mm | 50*100mm3mm |

| Maximum rectangular tube diameter(Flat bend)Maximum wall thickness | 10*20mm2mm | 20*30mm3mm | 20*40mm3mm | 30*50mm3mm | 40*80mm3mm |

Hydraulic Rebar Bender: Technical Analysis and Core Advantages

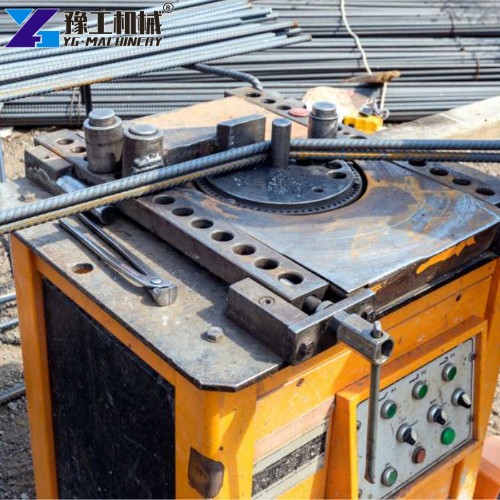

The working principle of YG Machinery’s hydraulic rebar bender is both simple and efficient. It uses a hydraulic system to apply precise, controlled pressure to bend rebar to a preset angle. The entire process—from clamping the rebar firmly in the die, to the hydraulic cylinder initiating the bend, to the automatic release upon completion—is seamless. This design offers several technical advantages:

- Increased Efficiency: The automated bending process significantly speeds up work. Our machine can replace 20-30 workers, drastically saving labor costs and boosting productivity.

- Quality Assurance and High Precision: Hydraulic power ensures precise control and repeatability of bending angles. Every rebar meets strict project specifications, reducing waste and guaranteeing quality.

- Exceptional Durability: We use high-quality corrosion-resistant materials and a robust frame, ensuring the equipment operates stably for a long time in harsh construction environments, extending its service life.

- Cost-Effectiveness: While there’s an initial investment, the high production capacity and low maintenance needs make the hydraulic rebar bending machine price highly cost-effective in the long run, offering a quick return on investment.

- Safety Features: Equipped with an emergency stop button and safety guards, the machine maximizes operator safety.

Hydraulic Rebar Bender Q&A

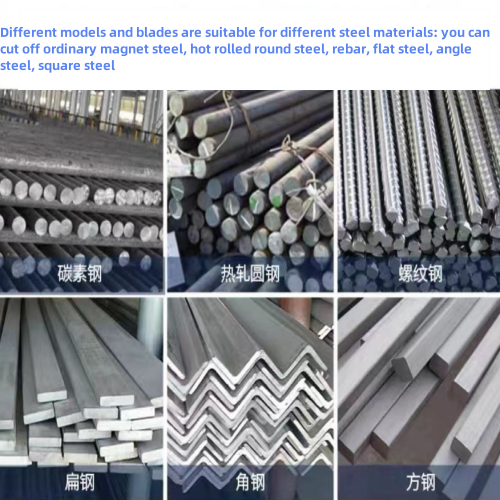

Our hydraulic rebar bender comes in various models and can easily handle different rebar diameters, meeting the needs of most construction projects.

Our portable hydraulic rebar bender for sale model has a compact design, making it easy to transport and operate. It’s perfect for customers who need flexibility across multiple job sites.

Our machines are well-designed with durable components. Maintenance usually involves only a simple check of the hydraulic oil and lubrication of key parts, keeping costs very low.

Extensive Applications of Hydraulic Rebar Bender in Concrete Construction

The hydraulic rebar bender for concrete construction is an indispensable tool in modern projects. Its applications include:

- Building Construction: Bending rebar for foundations, columns, beams, and slabs.

- Infrastructure Projects: Shaping rebar for bridges, tunnels, and road construction.

- Industrial Facilities: Pre-shaping rebar for large structures like tanks and silos.

For instance, our customer Roberto in South America, who runs a medium-sized construction company, saw a 70% increase in rebar shaping efficiency after acquiring our hydraulic rebar bender. A bending task that used to take three days can now be completed in just one. This not only helped him shorten delivery times but also significantly reduced project scrap rates, earning him more valuable contracts.

How to Choose the Right Hydraulic Rebar Bender?

Selecting the right hydraulic rebar bending machine involves several factors. First, determine the required bending diameter and bending angle range based on your project needs. Next, consider the machine’s working efficiency and portability. Finally, look into its durability and available after-sales service. With over 20 years of experience in construction machinery, YG Machinery can tailor the most suitable solution for your specific needs. We also provide detailed machine operation training to ensure your team gets up to speed quickly.

Ensuring Bending Accuracy: The Importance of the Hydraulic System

The pressure stability of the hydraulic system directly determines the precision and consistency of rebar bending. We use an advanced hydraulic system to ensure a stable pressure output throughout the bending process, achieving exceptionally high repeatability. Furthermore, the system’s flow control technology is crucial, as it precisely regulates the bending speed to prevent rebar from breaking or deforming due to excessive speed. Therefore, choosing a hydraulic rebar bender with a superior hydraulic system is key to ensuring project quality.

Boosting Bending Efficiency: Automation and CNC Technology

CNC technology is another major key to improving the efficiency of the hydraulic rebar bender. Our machines feature a microcomputer control system, allowing the operator to simply input the desired bending parameters on the control panel, and the machine automatically completes all operations. This automation not only simplifies operation but also significantly boosts production efficiency. Compared to traditional manual or semi-automatic equipment, a CNC hydraulic rebar bending machine can drastically shorten the bending cycle, making it especially suitable for large-scale, high-demand construction projects.

Take Action Now to Get Your Exclusive Quote

Still struggling with rebar bending challenges? Contact us today to get a free quote and exclusive solution for our hydraulic rebar bending machine.

As a company with more than 20 years of experience in construction machinery, YG Machinery also has other steel bar equipment for you to choose from, rebar straightening and cutting machines, rebar threading machines, automatic pipe bending machines, steel hoop bending machines, stirrup bending machines, steel bar cutting machines, reinforced cage winding machines, chain link fence machines, etc. Contact us for more machine details!