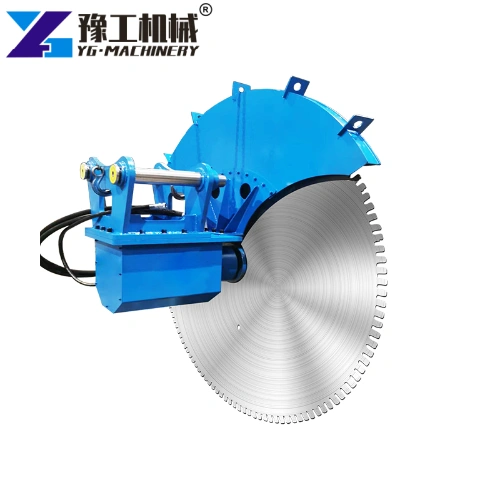

The YG excavator rock saw is a hydraulically driven cutting attachment mounted on excavators, primarily used for precise cutting, grooving, and trimming of hard materials such as rock, concrete, and brick walls. Its core characteristics lie in the powerful hydraulic drive that rotates the saw blade at high speed, generating a strong cutting force to efficiently and accurately cut rocks of various hardness. Some models of the rock saw attachment also have lateral movement and angle adjustment functions to suit different cutting needs. The saw blade can also be replaced with a logging saw blade, a rock saw attachment for forestry logging. In addition, this equipment can be designed and installed according to your other equipment, and the product is tailored for you.

Parameters of YG Excavator Saw

| Model | YG-CF1 | YG-CF2 | YG-CF3 | YG-CF4 |

| Suitable for excavators | 2~4T | 6~9T | 10~18T | 20~30T |

| Saw Disc Diameter | 0.4~0.8M | 1.2~1.6M | 1.8~2.2M | 2~2.8M |

| Cutting width | 5mm | 9mm | 14mm | 20mm |

| Cutting depth | ≤400mm | ≤800mm | ≤1100mm | ≤1400mm |

| Pressure | 30Mpa | 30Mpa | 30Mpa | 30Mpa |

| Flow | 30L/min | 80L/min | 120L/min | 190L/min |

YG Excavator Saw Attachment: Wide Application Scenarios

- Mining: Utilizing the powerful rock saw attachment for an excavator for rock cutting and ore body separation to achieve regularized mining and improve the utilization rate of mineral resources.

- Tunnel excavation: Tunnel profile cutting, pilot tunnel excavation, and treatment of unfavorable geological conditions.

- Building stone processing: Precisely cutting stone blocks, processing special-shaped stones, and creating decorative lines to enhance the added value of stone products.

- Municipal engineering: Using the excavator hydraulic rock saw for precise cutting of concrete pavements, excavating trenches, and removing obstacles to reduce the impact on the surrounding environment.

- Landscape architecture: Artificial rockery shaping, stone cutting, and landscape stone processing.

- Water conservancy projects: Rock excavation and channel trimming.

7 Features of Rock Saw Attachment

- Efficient and precise cutting: Powerful hydraulic power and high-hardness saw blades ensure cutting efficiency and precision. As a professional rock saw, it can easily handle the rock cutting needs of various hardness levels.

- Low noise and low dust: Compared to traditional methods such as blasting, the excavator hydraulic rock saw cutting process produces less noise and dust pollution, making it more environmentally friendly.

- High safety: Simple operation avoids high-risk operations such as blasting, ensuring the safety of construction personnel.

- Flexible and convenient: Mounted on the excavator, it is easy to move and has a wide operating range, enabling quick adaptation to different work sites.

- Multiple cutting modes: It can perform straight cutting, curve cutting, grooving, and other operations to meet different project requirements.

- Optional functions: Some models have lateral movement and angle adjustment functions, making the rock saw for excavators more adaptable and capable of handling more complex cutting tasks.

- Low maintenance cost: Compact structure, easy to maintain, reducing long-term operating costs.

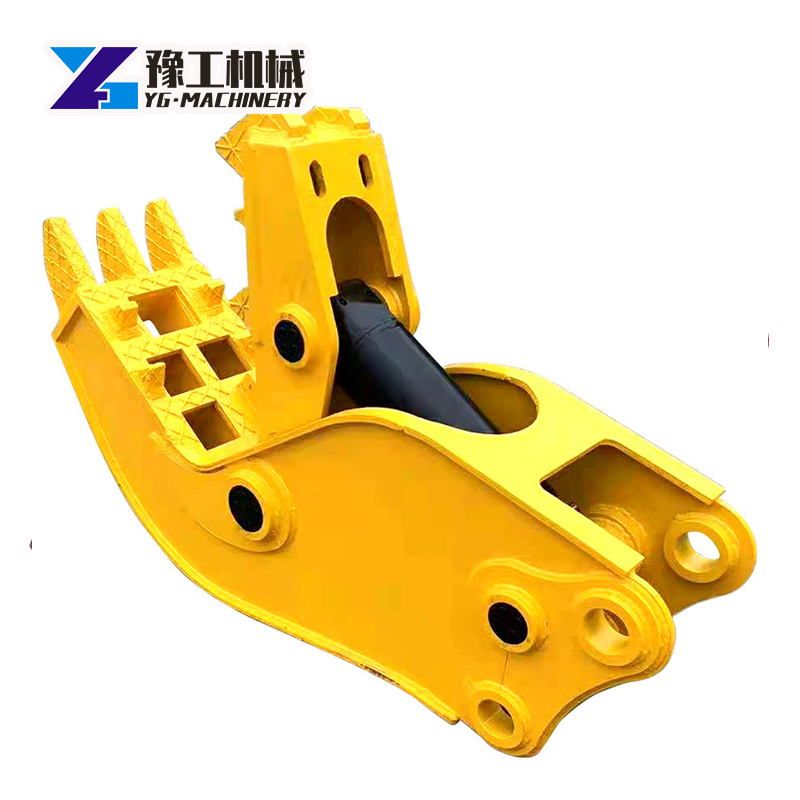

Excavator Saw Attachment for Sale– YG Machinery

According to the requirements of the operation, we provide two types of saw teeth: One with replaceable teeth and the other with non-changeable teeth. Due to the high requirements for the operation of the hydraulic rock saws, we provide wear-resistant teeth with full protection. Their special process design and high-strength wear-resistant materials ensure high efficiency during operation. This product is easy to disassemble and assemble and has high cutting efficiency. Sawing the rock and then using the crushing hammer to strike the quarry greatly improves efficiency and saves costs. Contact us now to learn more about YG rock saw attachment for excavator product information and preferential quotes. Our professional team will provide you with the most suitable solution.