The egg crate making machine, also known as a pulp molding machine, is a device that molds paper pulp into various packaging products. This machine is primarily designed for producing egg cartons, but it’s versatile enough to create coffee cup holders, fruit trays, and a variety of other items depending on the needs. The egg carton making machine plays a crucial role in modern packaging, especially when it comes to safely packaging eggs and other fragile products.

There are three main types of egg crate making machine, categorized by their molding methods: flap machines, rotary drum machines, and reciprocating machines. No matter which type you choose, they all share the same essential purpose: to produce paper pulp egg cartons that safeguard eggs during transport and handling. For instance, YG’s fully automatic drum-type egg box making machine can churn out an impressive 7,000 pieces per hour, and it offers customizable mold designs to fit your specific requirements.

Egg Crate Making Machine Popular Models

We have different egg tray production lines with different outputs and configurations according to the different needs of customers and budgets.

| Model | Output(pcs/h) | Mould Quantity | Total Power(kW) | Raw Materials (kg/h) |

| DT-1*3 | 1000 | 1*3+3 | 41 | 23.8 |

| DT-1*4 | 1500 | 1*4+4 | 41 | 28.4 |

| DT-3*4 | 2000 | 3*4+3 | 53.7 | 32.57 |

| DT-4*4 | 3000 | 4*4+4 | 57 | 39.9 |

| DT-4*8 | 4000 | 4*8+4 | 90 | 63 |

| DT-5*8 | 5000-6000 | 5*8+5 | 150 | 105 |

| DT-5*12 | 6000-7000 | 5*12+5 | 153 | 107.1 |

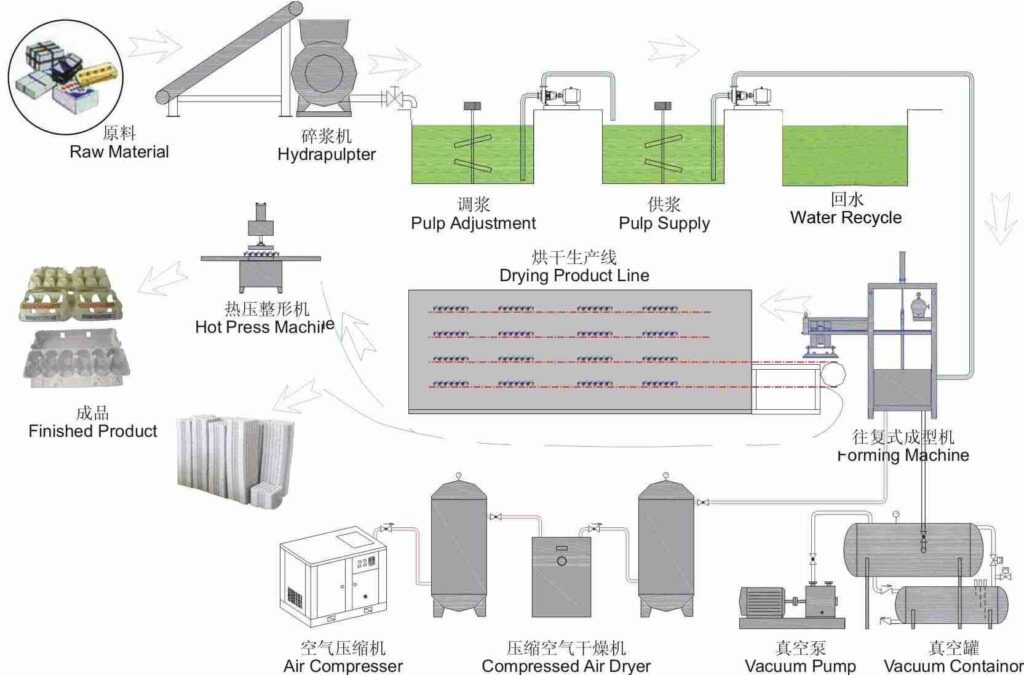

The Production Process of Egg Cartons

- Pulping: Waste paper and water are mixed at a 1:10 ratio in a pulper. The consistency is adjusted to 3%-5% through a pulping tank and supply tank. YG’s automated system monitors concentration in real-time, eliminating quality issues caused by manual errors.

- Forming: A vacuum pump draws pulp onto molds. After dehydration, compressed air transfers the formed trays to pallets. YG’s aluminum molds, with a lifespan exceeding 5 years, ensure structural integrity.

- Drying: Trays are dried at 180-220°C for 15-20 minutes, reducing moisture to below 8%, after which they are stacked and packed.YG’s multi-layer metal drying system (18m×6 layers) processes 7,000 pieces per hour, cutting energy consumption by 30% compared to traditional drying methods.

Egg Carton Drying Methods

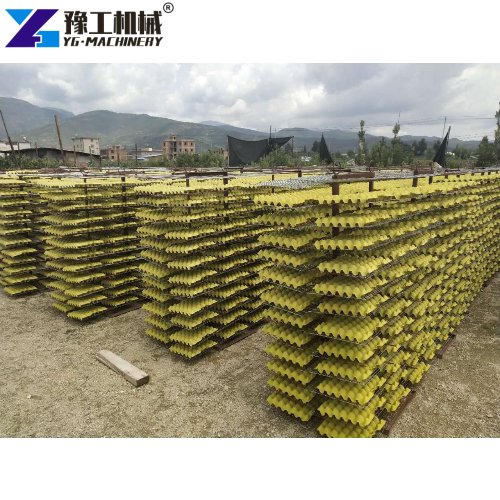

Sun Drying

Involves placing formed egg trays on drying racks and exposing them to sunlight and natural wind in an open area. This method typically requires 100-200 racks, with each rack holding 24-30 mesh trays, and each mesh tray accommodating 3-4 egg trays.

- Advantages: Zero energy consumption for drying, significantly reducing production costs.

- Disadvantages: Requires substantial manual labor, large land footprint, and is susceptible to weather conditions.

Drying Box

Once the egg trays are formed, they’re set on galvanized trays and loaded onto drying racks before being pushed into a drying box. The trays spend about half an hour in the heat to ensure they’re completely dry. Each box can hold 10 to 12 trolleys, and each trolley can carry between 90 and 100 egg trays. For a smooth operation, it’s a good idea to have an extra 10 trolleys on hand for continuous cycling.

- Advantages: Unaffected by wind or rain, smaller land footprint.

- Disadvantages: Requires more manual labor.

Brick Drying Line (Civil Construction Drying)

Formed egg trays enter a drying tunnel via a conveyor belt and are dried at 180-200 degrees Celsius for about 15 minutes before exiting the other end. These tunnels typically span 40-70 meters in length. Fuel options include coal, wood, natural gas, or diesel.

- Advantages: Lower construction cost compared to multi-layer dryers.

- Disadvantages: Long land footprint, higher drying costs.

Multi-Layer Metal Drying Line

Formed egg trays enter the drying chamber via trays and undergo 6 layers of drying at 180-200 degrees Celsius for 25 minutes, then exit from the bottom. The drying chamber measures 18 meters in length across 6 layers. Fuel options include coal, wood, natural gas, or diesel.

- Advantages: Small land footprint, effective energy savings, high degree of automation.

- Disadvantages: Higher initial investment.

View Sales Cases of YG Egg Tray Machine

- Successful Case of Egg Tray Production Machine in Saudi Arabia

- Egg Tray Making Machine Sold to Colombia

- Egg Carton Machine Sold to Peru

Egg Crate Making Machine Manufacturer – YG Machinery

With 18 years of expertise, YG has delivered 5,000+ solutions to 120+ countries. Certified sustainability: CE, ISO, SGS certified, with 90% wastewater recycling. Customization: Support mold design (e.g., 12-cell egg boxes, fruit trays), color printing, and logo branding. Whether you need a basic production line or a fully automated system, YG provides turnkey services from installation to after-sales support. Our engineers have optimized production costs for clients in Spain, the US, and South Africa.

Click below for a free quote and join us in driving sustainable packaging innovation!