The dredging equipment market is experiencing rapid growth, with global CAGR projected to reach 17.6% by 2025. This growth directly impacts the product dredging robot price and technological development. Understanding current market trends helps in making more informed purchasing decisions.

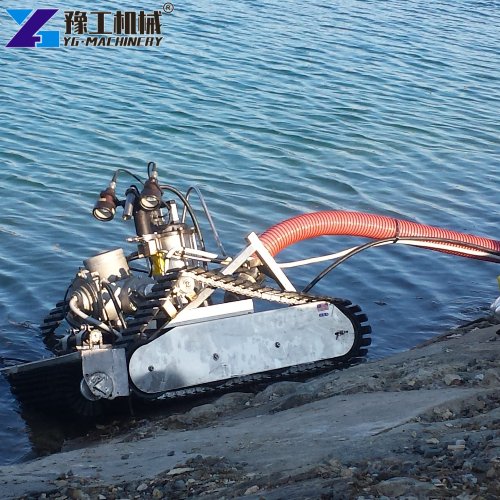

YG Machinery specialises in comprehensive automated dredging solutions. Our product line ranges from basic small dredging machine to advanced crawler dredging robot systems, each designed for specific application scenarios. Reasonable investment considers not only initial costs but also long-term operational benefits.

Dredging Robot Parameter:

| Dimension: | 1220*890*520mm | Speed: | 2.5-4KM/h |

| Self Weight: | 120kg | Designed Load: | 100-300kg |

| Waterproof: | IP68 | Rated Torque: | 100-500 NM |

| Track Width: | 130mm | Reducer Efficiency: | 65-85% |

| Gear Ratio: | 1:10-1:40 | Motor Voltage: | 380ACV (customized as local voltage) |

| Motor: | 0.75-1.5KW*2 | Climbing Ability: | ≤30°(can climb stairs) |

| Motor Rated Speed: | 1500r/min | Maximum Span: | 620mm |

| Cable Control Distance: | Standard 50m, maximum 150m | Over-Obstacle Capacity: | 130mm |

| Maximum Underwater Depth: | 30m | Power Supply: | Generator or 380V power supply |

Key Factors Determining Dredging Robot Price

Technical Specifications and Performance Capabilities

Equipment technical configuration is the primary factor affecting the dredging robot price. Models with higher production capacity, such as those achieving 200m³/h processing capacity, typically target the high-end market. Slurry pump system performance, measured by 15-meter head, directly impacts work efficiency and final pricing.

Advanced features like underwater navigation sensors and automatic sludge removal systems significantly influence final dredging robot price. These technological innovations improve operational accuracy while reducing manual intervention requirements. Crawler drive systems provide excellent traction on various terrains but involve higher manufacturing costs.

Automation Level

Automation level represents another crucial consideration. Fully autonomous systems with AI navigation command significantly higher dredging robot price than semi-autonomous or remote-controlled models. These high-end systems integrate underwater crawler robot technology with GPS positioning for precise operations.

Real-time monitoring systems increase initial investment but effectively reduce long-term operational costs. portable dredge remote control capabilities raise base quotes while significantly enhancing operational safety in hazardous environments. Modular design philosophy allows customers to select feature combinations based on actual needs.

Product Series and Price Range

Economical Solutions

For budget-conscious users, we offer multiple small dredging machine models. These compact systems strike a good balance between performance and cost. Electric models use 220V standard voltage, ensuring reliability while reducing energy consumption. The 1250mm working width enables adaptation to various confined spaces.

A basic small dredging machine represents the most accessible dredging robot price range while ensuring professional-grade performance. These units are particularly suitable for environmental remediation projects and small water areas. Despite their economic positioning, they retain core functions like automatic sludge removal.

Professional Configurations

For demanding application scenarios, our crawler dredging robot series delivers exceptional performance. These robust systems excel in complex terrain with outstanding operational stability. The 3-9M/min travel speed, combined with enhanced traction, ensures reliable operation on slippery surfaces.

This series includes various specialised configurations, including river silt cleaning machines and septic tank dredging machine versions. Each design optimises cost-effectiveness for specific working conditions. The tank cleaning robot is specifically designed for industrial tank cleaning needs, providing efficient and safe solutions.

Dredging Robot Application Scenario Analysis

Environmental Remediation

Environmental projects typically require strict budget control, making dredging robot price a key consideration. Our river silt cleaning machine solutions provide cost-effective automated processing for water channels. These devices usually fall within the medium price range, balancing performance and cost.

septic tank dredging machine targets municipal and industrial applications. Their quotes reflect additional costs for specialised components and safety features. Despite their specialised nature, these systems offer significant long-term value through reduced maintenance requirements and enhanced operational safety.

Industrial Applications

The industrial sector often prioritizes production efficiency, making it more receptive to higher equipment investment. Our tank cleaning robot provides efficient maintenance for various storage facilities. Their prices include special attachments and safety devices suitable for confined space operations.

crawler dredging robot excels in special environment applications, using anti-corrosion materials to withstand harsh working conditions. High-end dredging kits integrate advanced monitoring systems and precise sediment handling capabilities.

Return on Investment Analysis

Cost Structure

Complete cost assessment should include long-term operational expenses. Although high-end models require higher initial investment, the benefits from improved operational efficiency are often more significant. Electric equipment, despite higher purchase costs, substantially reduces energy consumption compared to diesel-powered models.

Maintenance requirements also affect total ownership cost. Models with modular design, though slightly higher in initial dredging robot price, significantly reduce maintenance costs and downtime. The one-year warranty provides additional protection for initial operations.

Benefit Evaluation

ROI analysis should comprehensively consider potential benefits. In scenarios requiring continuous automated operation, premium systems typically deliver the best returns. The premium cost for automation is often compensated through labor savings and efficiency improvements.

small dredging machine usually offers the fastest payback period for budget-limited users. These units maintain professional performance while providing competitive entry-level prices. portable dredge represents another high-return option due to its economy and applicability.

Dredging Robot Price FAQ

Prices vary significantly depending on configuration. Standard-configured small dredging machine typically ranges between $10,000 and $30,000. Enhanced-function crawler dredging robot may reach around $20,000. Specific dredging robot price depends on automation level, processing capacity, and special feature requirements.

Fully autonomous systems have 30-50% higher dredging robot price than semi-automatic models. This premium mainly comes from R&D costs for advanced sensors, navigation systems, and control software. However, higher initial investment is typically compensated through improved operational efficiency.

Beyond equipment quotes, consider potential expenses for transportation, training, maintenance, and accessories. Regular maintenance typically adds 10-15% to annual operating budgets. Special applications may require custom attachments, affecting total investment. Energy consumption differences are also important factors.

Service and Support

Quality Commitment

We ensure each dredging robot price plan includes comprehensive quality assurance. All products undergo rigorous testing before delivery. The one-year warranty provides complete protection for initial operations, covering parts and labor related to manufacturing defects.

Professional technical teams are dedicated to maximizing customers’ equipment investment value. We provide complete operation training and maintenance guidance. These support measures ensure optimal user experience regardless of the chosen price range.

Customization Services

We offer extensive customization options to help customers optimize cost-effectiveness. The modular design concept supports on-demand feature configuration. This flexibility ensures users pay only for functions they actually need.

We can develop specialized versions including river silt cleaning machine, tank cleaning robot, and septic tank dredging machine configurations. Each custom solution receives precise pricing based on specific functional requirements. Engineering teams work closely with clients to develop the most valuable solutions.

Get Your Customised Solution

Understanding the factors affecting dredging robot price helps formulate optimal procurement strategies. We provide transparent pricing systems and detailed technical consultation. Professional teams are ready to offer comprehensive product information and application advice.

Contact YG Machinery for personalized dredging robot price quotes. We’ll provide detailed specifications and configuration recommendations. Let us help you find the most suitable dredging robot solution to ensure maximum return on your investment.