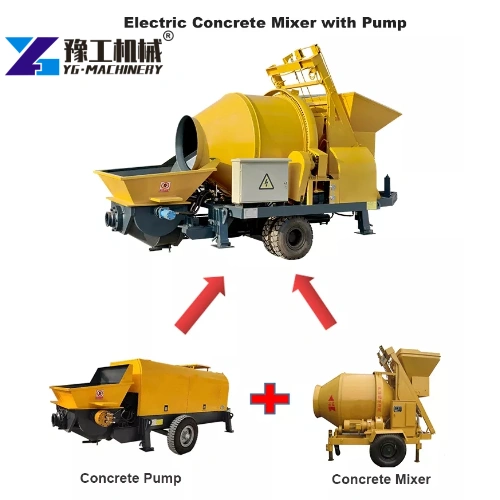

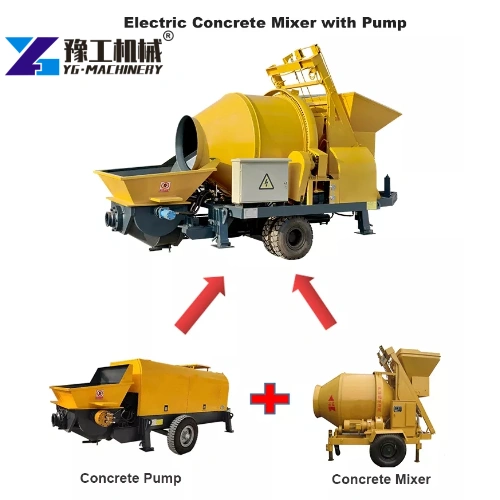

Are you searching for a solution that combines onsite mixing and high-pressure pumping? The concrete mixer and pumping machine is your single answer for high efficiency and lower costs. It simplifies complex construction processes into one step. This not only saves your site space but also significantly cuts labor and fuel consumption. This machine is specially engineered for remote locations and challenging projects.

Parameters of Concrete Mixer and Pumping Machine

| Model | YG-350 | YG-550 |

| Theoretical delivery volume | 20-30M3/h | 40M3/h |

| Bone particle diameter | 0.5-40mm | 20-40mm |

| Greatest pressure | 20mpa | 20mpa |

| Bore*Stroke | 180*1000mm | 200*1110mm |

| Motor Power | 45kw | 55kw |

| Oil pump power | 100(column)L/S | 140(column)L/S |

| Delivery pipe | 125mm | 125mm |

| Genset power | 150kw | 150kw |

| Machine size | 6100*2000*2700mm | 6200*2000*2700mm |

| Weight | 5500kg | 6500kg |

Max Transfer Distance: Up to $200m$ horizontally and $50m$ vertically.

Max Aggregate Size: Easily handles aggregates up to $40mm$ in diameter.

Output Volume: Offers selectable outputs of $20-45m^3/h$, fitting diverse project needs.

Power Option: Available in Diesel or Electric ($380V$).

Certification: CE International Certified.

Core Advantage: Why Choose YG’s Concrete Mixer and Pumping Machine?

Diesel Power and Stable Output

YG offers a robust diesel concrete mixer with pump configuration. It features an optimized hydraulic system. This delivers consistent and stable high pressure, even on sites without reliable grid power. This ensures dependable construction scheduling.

Superior Mixing and Transfer Efficiency

The machine’s drum design guarantees a high standard of mixing efficiency. Concrete can be pumped immediately after mixing. This maximizes your output volume for the job. It effectively replaces both a stand-alone mixer and a separate concrete pump.

Low Maintenance and High Durability

We prioritize low maintenance costs. Key wear parts are manufactured from high-strength alloy steel. Furthermore, the simple design allows site operators to perform routine maintenance easily. This ensures the machine’s high continuous operation time.

Portable Concrete Mixer with Pump Application Scenarios

If your operations involve the following scenarios, our machine is your ideal choice:

- Rural and Mountain Construction: The portable concrete mixer with pump offers high mobility. It easily accesses remote sites where large pump trucks cannot go.

- Tunnel and Mining Projects: Suitable for narrow spaces needing fast onsite preparation and immediate pumping of shotcrete.

- Small Infrastructure: Bridges, culverts, and water conservancy projects require a stable and precise concrete mixer and pumping machine.

Client Testimony: High-Efficiency Feedback from Saudi Arabia

Mr. Abdullah in Saudi Arabia adopted our concrete mixer pump machine for a major residential development. His main problems were concrete segregation and difficult remote material feeding. By using our diesel model, he achieved:

- 30% Schedule Acceleration: On-site instant mixing guaranteed the concrete’s freshness.

- Labor Savings: One machine replaced two pieces of equipment, cutting operator requirements.

- Waste Elimination: Precise output volume control reduced material waste significantly.

Return on Investment: How Our Cement Mixer and Pump Cuts Operational Costs?

When evaluating the cost of a cement mixer and pump, long-term value must be considered.

- Low Fuel Consumption: Our optimized design minimizes diesel usage while maintaining high pressure.

- Factory Direct Price: As the manufacturer, we provide you with a highly competitive factory-direct price.

- High Return on Investment (ROI): The machine’s efficiency and reliability ensure your capital is recovered quickly.

Call to Action: Get Your Concrete Mixer and Pumping Machine Quote Now

Do not settle for chaotic sites and high operating costs. Choose the YG Machinery concrete mixer and pumping machine. We offer worldwide shipping, customized solutions, and expert remote technical support.

Contact Us: Send an inquiry immediately to get your free price quote and detailed technical specifications!