In modern industrial manufacturing, pipe bending is a crucial process. Traditional bending methods are inefficient, lack precision, and lead to material waste. How can you increase production efficiency, lower costs, and ensure product quality? The automatic pipe bender is the perfect solution. With its exceptional automation capabilities, it has become a revolutionary tool. As a professional machinery manufacturer, YG Machinery’s automated pipe bender leverages cutting-edge technology to offer revolutionary bending solutions for the furniture, automotive, and construction industries.

Parameters of the Automatic Pipe Bender

| Model | Technical Parameter | |

| YG-RB40 | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-32 | |

| Round Bar Diameter(mm) | 6-40 | |

| Weight(kg) | 100 | |

| Dimension(mm) | 800*790*780 | |

| YG-RB42 | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-36 | |

| Round Bar Diameter(mm) | 6-42 | |

| Weight(kg) | 240 | |

| Dimension(mm) | 910*755*800 | |

| YG-RB50 | Motor Power(kW) | 4 |

| Rebar Diameter(mm) | 6-40 | |

| Round Bar Diameter(mm) | 6-50 | |

| Weight(kg) | 320 | |

| Dimension(mm) | 995*805*770 | |

YG Machinery Automatic Pipe Bender: Technical Analysis and Key Advantages

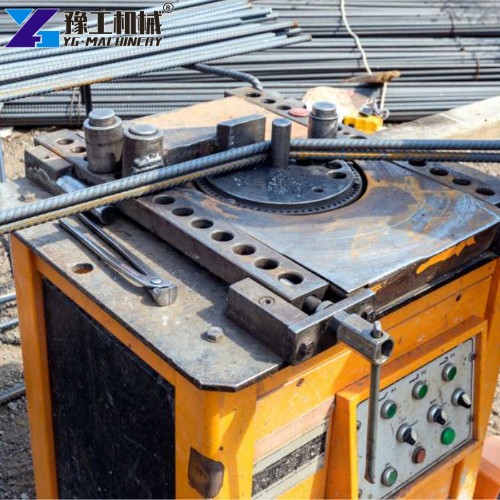

YG Machinery’s automatic pipe bender uses advanced CNC technology for automated and intelligent bending. By pre-setting programs, the machine precisely controls bending angles, radii, and speed, ensuring high consistency in every bend. Its core advantages include:

- Massive Efficiency Boost: Our high-speed automatic pipe bender uses an efficient motor and an optimized motion control system to shorten bending cycles significantly. It completes multiple bends quickly and precisely, greatly increasing production efficiency.

- High Precision and Quality: With CNC programming, our machine achieves angle control accurate to ±0.1°, ensuring products meet stringent industry standards. This reduces scrap rates and enhances the quality of the final product.

- Versatility and Flexibility: YG Machinery’s automatic pipe bender can bend various round pipes and, by changing dies, can also bend square and rectangular tubes, or even be used as a hydraulic flat bar bender, offering multiple functionalities in one machine.

- Cost-Effectiveness: While there’s an initial investment, automated production reduces reliance on manual labor, lowering labor costs. High-precision bending also minimises material waste, improving material utilization, leading to a high return on investment in the long run.

- Ease of Operation: The machine comes with an intuitive touch screen interface and a parameter memory function. Operators can be trained quickly, which reduces operational difficulty and minimises human error.

Automatic Pipe Bender Q&A

No. Our machine’s interface is very user-friendly. Even beginners can quickly master it with simple training.

Yes. Our machine has a powerful hydraulic drive system. By changing the appropriate dies, it can be used as a hydraulic flat bar bender or a hydraulic bar bender to easily bend flat bars and various profiles.

Extensive Applications and Case Studies of the Automatic Pipe Bender

The automated pipe bender is widely used in furniture, automotive, construction, and aerospace industries. It provides an efficient and reliable solution for producing various complex pipe components.

- Furniture Manufacturing: Bending frames for tables, chairs, and beds.

- Automotive Parts: Manufacturing exhaust pipes, seat frames, and bumper guards.

- Architectural Decoration: Bending handrails, railings, and various decorative pipe fittings.

Here’s a success story: Our client Javier from Spain runs a medium-sized furniture manufacturing factory. After implementing our automatic pipe bender, his production efficiency increased by 50%, raising his daily output from 500 to 750 pieces. With a significant improvement in bending precision, the scrap rate dropped by 8%, saving him tens of thousands of dollars in material costs annually. Javier specifically mentioned that the high speed and stability of our automatic pipe bender were key factors in his decision to choose YG Machinery.

Ensuring Bending Precision: CNC Programming and Angle Control

High-precision bending relies on CNC programming and accurate angle control. Our automatic pipe bender uses an advanced microcomputer control system, allowing operators to input precise bending angles, radii, and springback compensation values. The system automatically calculates and executes the bending action, ensuring each product meets the preset geometric shape. This level of precision is unmatched by traditional manual or semi-automatic machines. It completely solves issues of inconsistent bends and inaccurate angles, greatly improving the product qualification rate.

Optimizing Production Flow: From Material Utilization to Motion Control

Optimising the production process isn’t just about increasing bending speed. Our automatic pipe bender is designed with the entire production flow in mind. Through precise CNC programming, the machine minimises material waste, increasing material utilisation. At the same time, our advanced motion control system ensures smooth and steady movement during bending, reducing mechanical wear and extending the equipment’s service life. This saves on maintenance costs and guarantees production continuity and stability.

Expanding Applications: Versatile Bending from Round Pipes to Flat Bars

Our automatic pipe bender isn’t limited to bending round pipes. Its modular design and interchangeable dies allow it to handle different cross-sectional shapes with ease. For example, by fitting specialised dies, it can function as a hydraulic flat bar bender or a hydraulic bar bender, effortlessly completing bending tasks for flat and square steel bars. This versatility significantly expands the machine’s application range, offering customers higher investment value and stronger market competitiveness.

Take Action Now and Customise Your Exclusive Bending Solution!

Looking for an automatic pipe bender that can boost your production efficiency? Contact us today for a free quote and a customised solution.

Related Products

As a professional rebar processing machinery manufacturer, we have a series of steel bar machinery for sale. Our product mainly includes rebar straightening and cutting machine, rebar bending machine, rebar bender for sale, scrap rebar straightening machine. Automatic steel bar cutting machine, steel bar straightening machine, rebar upsetting machine, thread rolling machine, thread rebar couplers, beam bending machine, etc. What kind of rebar-related machine do you need? Please feel free to leave your requirements.