If you work in construction, you know how crucial it is to have the right tools. A reliable vibratory pile driver can make or break a project. So, what is a vibratory pile hammer? It’s a powerful machine used for driving or extracting piles, sheets, and other foundations. This tool uses high-frequency vibration to reduce friction in the soil. This allows the pile to be installed quickly and quietly.

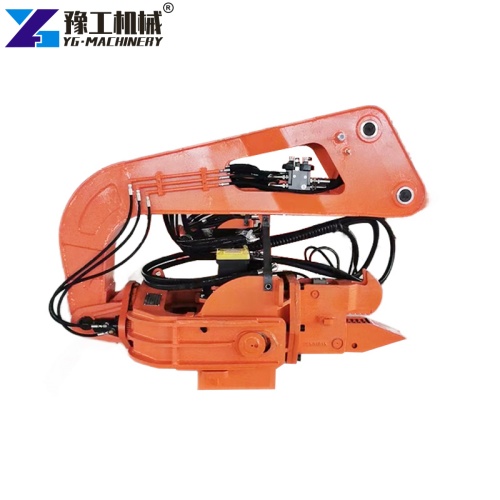

Whether you need a vibratory hammer for excavator or an excavator mounted vibro hammer, choosing the right one is key. YG offers advanced vibratory pile hammer that solve common job site problems. Problems like low efficiency, high noise, and difficult soil conditions. We help you work smarter and faster.

Vibratory Pile Hammer Parameter:

| Model | YG150D | YG250D | YG350D | YG400D | YG450D |

| Eccentric moment(kg*m) | 3.2 | 5.1/5.7 | 7.1 | 9.2 | 11 |

| Speed(rpm) | 2600 | 2600 | 2600 | 2600 | 2600 |

| Excitation force(t) | 24 | 38/42 | 52 | 68 | 81 |

| Operating pressure of oil system(bar) | 200 | 300 | 320 | 330 | 330 |

| Flow demand for hydraulic oil system(lpm) | 100 | 163 | 220 | 260 | 300 |

| Weight(t) | 1.2 | 1.6 | 2.4 | 2.5 | 2.6 |

| Excavator(t) | 8-12 | 20-25 | 25-35 | 35-45 | 40-55 |

Understanding the YG Vibratory Pile Hammer: Features and Advantages

Our vibratory pile hammer is designed for maximum performance and durability. It works by using a powerful hydraulic motor to spin eccentric weights. This creates a strong vertical vibration. This vibration fluidizes the soil around the pile, reducing resistance.

This process is much more efficient than traditional impact hammers. Our excavator mounted pile driver provides better control and accuracy.

Core Benefits of YG’s Vibratory Pile Driver

- Exceptional Efficiency: Our vibratory pile hammer installs piles up to 30% faster than older methods. This saves you time and labor costs on every project. It reduces soil resistance for quick, smooth operation.

- Reduced Noise and Vibration: The high-frequency vibration system significantly lowers noise levels. This is ideal for urban areas or sites with strict noise regulations.

- Unmatched Durability: We use high-grade steel and robust components. This ensures a long service life and minimal maintenance. Our hydraulic pile driver for excavators is built to last. It handles tough jobs with ease.

- Versatile and Adaptable: Our vibratory pile hammer works with various pile types. This includes sheet piles, H-beams, and concrete piles. It’s a versatile tool for many applications.

- Superior Clamping Force: Our advanced clamping system ensures a firm grip on the pile. This prevents slippage and improves safety. We use premium hydraulic components for reliable performance.

Commonly Asked Questions About Vibratory Pile Hammer

Vibratory pile drivers are most effective in granular soils like sand and gravel. They can also be used in cohesive soils, but results may vary. For very dense or rocky ground, an impact hammer might be needed.

A mini excavator pile driver attachment is perfect for small-scale projects. Think of residential foundations or landscaping work. We offer different models to match your excavator’s size and your project’s needs.

The vibratory hammer for excavator uses your excavator’s hydraulic system for power. It generates vibrations to fluidize the soil. This makes it easy to drive or pull piles. The eccentric weights inside the hammer spin at high speed. This creates the powerful vertical force.

Diverse Applications and Proven Success

The YG vibratory pile hammer is used in many industries. It’s the perfect tool for civil engineering, marine construction, and infrastructure projects.

Case Study: The Florida Marina Project

An American client in Florida needed to install sheet piles for a new marina. The soil was sandy with high water saturation. Traditional methods were too slow and loud. They purchased our excavator pile driver for sale. The YG attachment was mounted on their excavator. The team was able to install piles quickly and quietly. This finished the project ahead of schedule. Our client reported a 45% increase in efficiency. The reduction in noise pleased local residents.

Other Applications Include:

- Road and Bridge Construction: Installing foundation piles for overpasses and bridges.

- Urban Development: Creating foundations for commercial buildings and retaining walls.

- Offshore Engineering: Driving piles for docks and jetties.

How to Choose the Right Vibratory Pile Hammer

Choosing the right vibratory pile hammer involves several factors. You need to consider the eccentric moment and frequency range. Higher eccentric moment means more driving force. Higher frequency is better for non-cohesive soils. Also, consider the pile size and your excavator’s hydraulic flow. This ensures a perfect match.

Our team provides expert consultation. We help you select the best excavator mounted pile driver for your specific needs. This makes sure you get the best value.

YG Company Strength and Service Commitment

YG is a trusted name in heavy machinery. Our products are exported to many countries. These include the USA, Canada, France, and Australia. We are known for our quality and reliability. We provide full support, from pre-sales consultation to after-sales service. Our team offers customized solutions and technical support. We also guarantee fast parts supply. Your success is our priority.

“We’ve used YG’s pile drivers for two years. They are robust and reliable. Their service team is always quick to help. I couldn’t be happier.” — Alex D., Project Manager, Canada.

Ready to Upgrade Your Equipment?

Stop wasting time with outdated methods. Invest in a YG vibratory pile hammer and boost your productivity. We have the right pile driver for sale for any job.

Contact us now to get a free quote. You can also learn about our customizable solutions. We also supply concrete pile breakers, scrap metal shear for excavators, hydraulic breaker hammers, hydraulic plate compactors, log grapple, car dismantling shear, excavator pile drivers, hydraulic magnet for excavator, hydraulic pulverizer, milling head for excavator, vehicle dismantler, hydraulic quick hitch, excavator rock saw, and other excavator attachments.