In modern construction, ensuring the safety and stability of structures relies heavily on high-quality rebar connections. However, traditional methods often suffer from low efficiency and inconsistent joint strength. To address these challenges, our rebar threading machine was created. This machine is designed for fast, high-quality processing of ribbed steel bar threads, significantly boosting your construction efficiency and connection quality.

Rebar Threading Machine Parameter:

| Model | YGS-40 | YGT-40 | YGA-40 |

| Processing diameter range | 16-40mm | ||

| Thread rolling length | 0-80mm | 0-80mm | 0-100mm |

| Power voltage | 4kw/380v 50hz | 4kw/380v 50hz | 7.5kw/380v 50hz |

| Working efficiency | 15s/forming | 8s/forming | One-touch auto forming |

| Machine weight | 320kg | 350kg | 400kg |

| Machine size | 115*50*106cm | 110*60*130cm | 126*70*106cm |

| Type | Standard type | Upgrade type | Full automatic type |

A Deep Dive into the Technical Advantages of YG’s Rebar Threading Machine

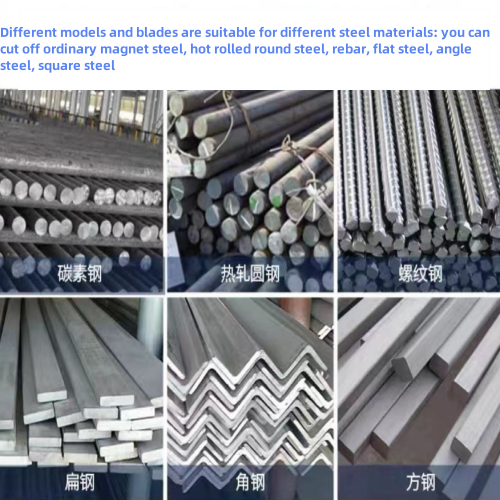

Our rebar threading machine integrates several innovative technologies. It uses an advanced cold extrusion forming process to process threads on HRB335 and HRB400 ribbed steel bars with diameters from 16-40mm.

Core Advantage 1: Dual Improvement in Efficiency and Quality

The core advantage of this machine lies in its unique design, which can simultaneously peel ribs and roll threads. Compared to traditional equipment, it combines two steps into a single operation, greatly saving time. The processed threads are full, have high-dimensional accuracy, and match the length of straight threads, ensuring reliability and safety in connections.

Core Advantage 2: Cost-Effectiveness and Durability

The non-cutting rolling technology can effectively enhance the internal and surface quality of the workpiece. The radial compressive stress generated during processing significantly increases the rebar’s fatigue strength and torsional strength. Furthermore, the high-quality rolling dies have a long lifespan, which reduces consumable costs.

Core Advantage 3: Automation and Ease of Use

Our rebar threading machine is highly automated. It is equipped with a unique tool auto-opening mechanism that allows for automatic knife opening and retraction. The operator only needs to set up the rebar once to complete the threading process, which greatly simplifies the operation.

Rebar Threading Machine Frequently Asked Questions by Customers (Q&A)

Rolled threads are a cold processing method that doesn’t cut the rebar fibers. It significantly increases the rebar’s tensile strength and fatigue strength, making the joint stronger than the parent material. Cut threads, on the other hand, can damage the fibers and reduce strength.

Our equipment prices vary based on the model, configuration, and specific requirements. You can contact us directly, and our sales team will provide a cost-effective quote for a thread rolling machine for sale based on your project’s needs and budget.

As a professional thread rolling machine manufacturer, we understand the importance of quality. Our machines are built with high-strength materials and feature a compact, stable design. The unique automatic tool-opening mechanism and robust frame ensure the equipment is durable and maintains consistent performance even under heavy-duty operations.

Rebar Threading Machine: Wide Applications and Success Stories

Our rebar threading machine is widely used in construction, bridges, tunnels, and other infrastructure projects.

Success Story: Matthew, a contractor in the Philippines, was managing a large commercial complex project. His challenge was that the old threading equipment was inefficient, causing project delays. After switching to our YG-40 rebar threading machine, they boosted rebar connection processing speed by 50% and reduced the defect rate by 15%. This not only shortened the delivery time but also significantly saved on labor costs, allowing the entire project to be completed on schedule.

YG Machinery’s Professional Advantages and Services

We are a leading thread rolling machine manufacturer with years of experience in the machinery export business. Our products are backed by international certifications like ISO and CE, ensuring global quality standards. Beyond offering high-quality equipment, we are dedicated to providing our customers with comprehensive solutions.

1. Comprehensive Service Guarantee

We offer professional pre-sales consulting and customized solutions to ensure you choose the most suitable equipment. Our complete after-sales service, including technical support, parts supply, and regular maintenance, gives you peace of mind.

2. In-Depth Technical Support

Our thread rolling machine for sale is more than just a machine; it’s a complete solution. We provide detailed operational training and technical guidance to ensure your team can use the equipment efficiently and safely.

Get Your YG Rebar Threading Machine Price Now!

Looking for high-quality, efficient rebar threading equipment? Our rebar threading machine is the perfect choice. Whether you need an automatic thread rolling machine to boost your production line’s automation or want to learn more about our hydraulic thread rolling machine, we are, in fact, here to offer expert support.

Contact us today to get a free quote and a customized solution. Visit our official website for more product details:

- YG Steel Bar Straightening and Cutting Machine

- YG Steel Bar Bending Machine

- YG Steel Bar Hoop Bending Machine