In today’s fast-changing market, the demand for efficient and environmentally friendly packaging solutions is constantly growing. Our YG Company, with years of professional experience, offers you top-of-the-line egg carton making machine to help you easily tackle production challenges. Our egg carton making machine solutions transform waste paper into high-quality pulp molded products, not only significantly boosting your production efficiency but also helping your business achieve sustainability goals. It’s a smart investment choice for you.

Egg Carton Making Machine Parameter:

| Model | YG-1*3 | YG-1*4 | YG-3*4 | YG-4*4 | YG-4*8 | YG-5*8 | YG-6*8 |

| Capacity (pcs/h) | 1000 | 1500 | 2500 | 3500 | 4500 | 5500 | 7000 |

| Forming Mould Quantity | 3 | 4 | 12 | 16 | 32 | 40 | 48 |

| Total Power (kW) | 40 | 40 | 50 | 60 | 130 | 140 | 186 |

| Electricity Consumption (kw/h) | 28 | 29 | 35 | 42 | 91 | 98 | 130 |

| Worker | 3-5 | 4-6 | 4-6 | 4-6 | 4-6 | 5-7 | 6-8 |

The Ideal Choice for Boosting Production Efficiency and Achieving Sustainable Development

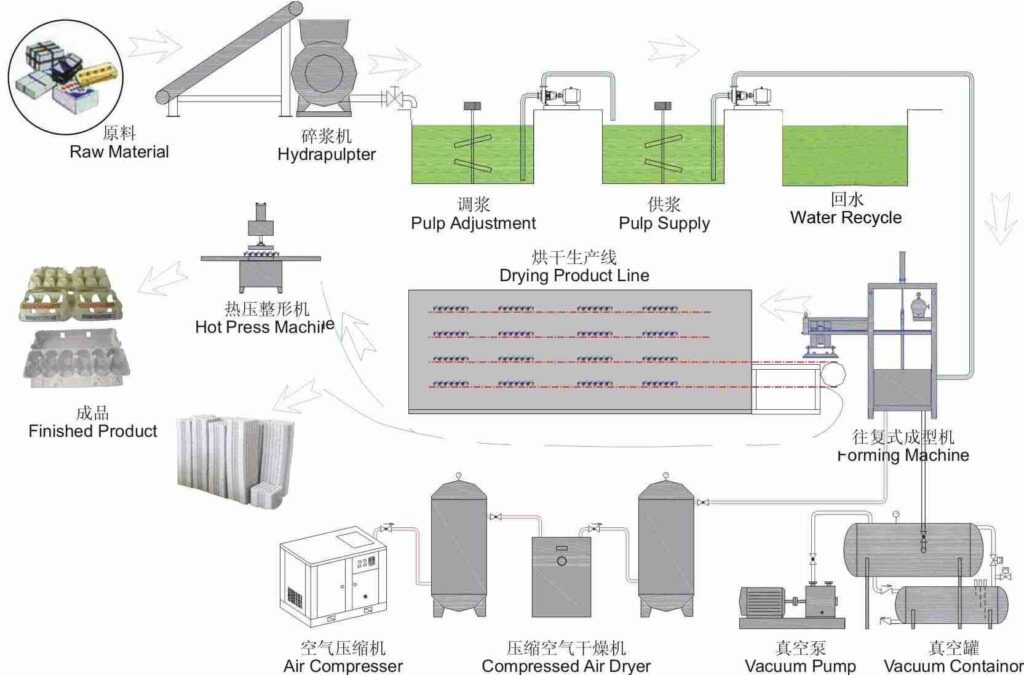

The primary purpose of an egg carton making machine is to convert waste paper into high-quality pulp molded egg cartons, widely used for packaging eggs, duck eggs, goose eggs, quail eggs, and other poultry eggs. Its working principle involves a series of automated processes, including pulping, molding, drying, and packaging, transforming waste paper (such as old newspapers, magazines, books, and used corrugated boxes) into sturdy and durable eco-friendly egg cartons.

Technical Advantages and Core Competitiveness of Our Egg Carton Making Machine

- Efficiency Enhancement: YG Company’s egg carton making machine employs a fully automatic control system, achieving a production capacity of 1000 to 7500 pieces per hour, significantly boosting production efficiency to meet the needs of various scale customers. Optimized design and process management ensure the equipment’s high-efficiency operation.

- Quality Assurance: Through precise vacuum forming technology and hot air drying systems, our egg carton making machine ensures that the final products possess excellent strength and hardness, effectively protecting eggs during transportation and storage, and reducing breakage rates. Moreover, the product complies with CE quality standards, ensuring international applicability.

- Cost-Effectiveness: Using inexpensive waste paper as raw material significantly reduces production costs. Compared to purchasing finished egg cartons, using our egg carton making machine can bring considerable economic benefits and accelerate return on investment. Furthermore, the energy-saving design of the egg carton making machine optimizes energy consumption, further lowering operating costs.

- Innovative Technology: We offer various models of egg carton making machine, from manual/semi-automatic equipment suitable for small-scale production to fully automatic production lines that meet large-scale production demands, flexibly adapting to customers’ different production capacities and automation needs. Additionally, by quickly changing molds, the same production line can produce different specifications of egg cartons, and even fruit trays, cup holders, and other pulp molded products, achieving product diversification.

- Eco-Friendly Production: The entire production process is 100% environmentally friendly, transforming waste into useful products, aligning with circular economy and sustainable development trends. The final products are fully biodegradable, reducing the burden on the environment and enhancing the company’s eco-friendly image.

Egg Carton Making Machine Q&A

Yes. Common paper and plastic tray can be done, but the mold should be customized aluminum mold.

1500 tablets per hour

Drying by air, drying oven, earth drying, metal drying.

The water used for production is recycled and not discharged, and it is always refilled with water, which evaporates when drying or drying wet trays.

Wide Application Scenarios and Success Stories of Egg Crate Making Machine

The application scope of egg crate making machine is extensive, extending beyond traditional poultry egg packaging to other agricultural and industrial products.

We once assisted a client from Vietnam, Mr. Zhang, who owns a large poultry farm. Facing increasing egg production and a demand for eco-friendly packaging, he decided to invest in YG’s egg crate making machine. By introducing our fully automatic egg crate making machine, Mr. Zhang’s factory achieved self-sufficiency in egg packaging, increasing production by 30% and reducing production costs by 25% due to the use of waste paper as raw material. More importantly, by using environmentally friendly pulp molded egg cartons, Mr. Zhang’s company established a positive environmental image locally, gaining more market recognition for its products.

How to Choose the Right Egg Carton Maker for Your Needs?

Choosing the right egg carton maker for your needs is crucial. Factors you need to consider include: production capacity requirements, automation level, budget constraints, and after-sales service.

If you are new to this field or have a limited budget, we recommend considering our small-scale paper egg tray making machine, which has a lower investment threshold but still guarantees reliable production capacity. These machines are easy to operate and maintain, making them ideal for small and medium-sized farms or packaging plants. Additionally, if you need to process specific types of waste paper raw materials, we will provide professional advice on pulping systems to ensure maximum raw material utilization and reduce production costs.

View Sales Cases of YG Egg Tray Machine

- Successful Case of Egg Tray Production Machine in Saudi Arabia

- Egg Tray Making Machine Sold to Colombia

- Egg Carton Machine Sold to Peru

Operational Costs and ROI Analysis of Egg Box Making Machine

Many customers are most concerned about the operational costs and return on investment (ROI) when investing in an egg box making machine.

The operational costs of an egg box making machine primarily include: raw material costs (waste paper), energy consumption (electricity, fuel), and labor costs. Since waste paper is widely available and inexpensive, this makes the raw material cost significantly lower than purchasing finished egg cartons. Our egg box making machine is designed with energy efficiency in mind, effectively reducing energy consumption. Furthermore, high automation reduces reliance on manual labor, further lowering labor costs. Overall, the egg box making machine offers considerable profit margins and a relatively short ROI period. For instance, based on feedback from our clients, many recover their investment within 1-2 years and start generating profits. We can also provide a detailed cost-benefit analysis report and ROI forecast based on your specific situation to help you make informed investment decisions.

YG Company Strength, Service, and Trust Building

YG Company possesses extensive experience and a distinguished position in the mechanical foreign trade sector. We specialize in the research, development, and production of egg box making machine, holding several patented technologies. Our factory is equipped with advanced production machinery and strictly adheres to ISO and CE quality certification standards, ensuring that every egg box making machine meets international leading standards.

We understand the importance of quality service to our customers. Therefore, YG Company provides comprehensive pre-sales consultation services, tailoring the most suitable egg carton machine solution for you based on your specific needs and market conditions. For after-sales, we offer thorough technical support, ample spare parts supply, and regular maintenance guidance to ensure your equipment operates stably for the long term. We are committed to building long-term partnerships with our clients; your success is our success.

“Partnering with YG Company was one of our smartest decisions! Their egg box making machine is not only of excellent quality, but their after-sales service is also incredibly prompt and professional. Our production efficiency has significantly improved, and product costs have been greatly reduced. Many thanks to the YG team for their professional support!” — Mr. Arevalo, a client from Colombia.

Contact Us Now for a Free Quote!