In modern construction and engineering projects, the demand for precision and efficiency in rebar processing is constantly increasing. Issues like bent or twisted rebar not only affect construction quality but also delay project progress and incur unnecessary costs. YG Machinery understands these industry pain points, and our bar straightening machine is designed precisely to solve these challenges. This highly efficient equipment can precisely straighten and cut various types of irregular rebar, significantly boosting your production efficiency and material utilization.

Technical Parameters of Bar Straightening Machine

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire Length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

Bar Straightening Machine: In-depth Analysis and Exceptional Technical Advantages

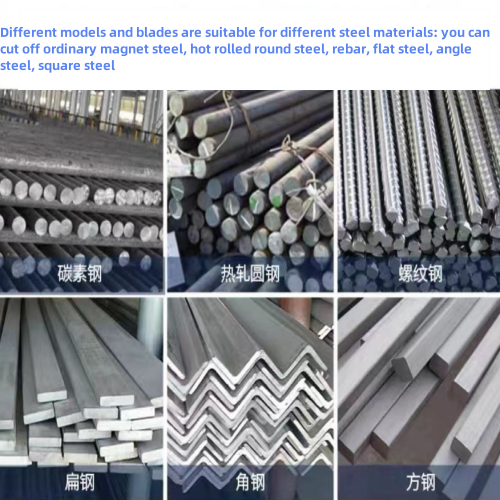

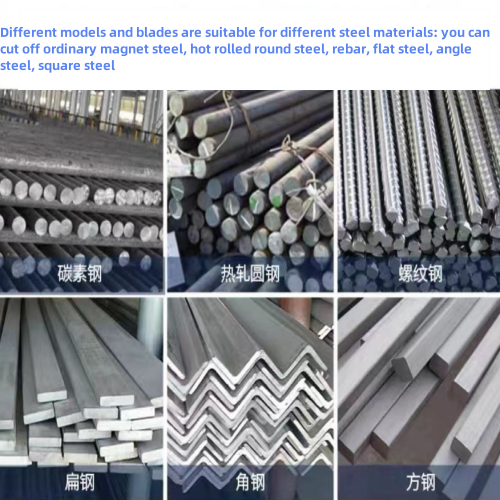

Our bar straightening machine integrates advanced technology with practical functionalities. It is primarily used for straightening and cutting various rebar materials, such as plain carbon steel, hot-rolled round steel, deformed bars, and cold-rolled rebar.

Key Product Features and Working Principle

The straightening mechanism of the bar straightening machine consists of straightening rollers, a straightening press, and bearings at both ends of the machine body. Power is supplied by a motor located at the bottom of the frame, driving the straightening shaft to rotate at high speed via a V-belt. The feeding mechanism comprises two synchronously operating pressure rollers. First, the rebar passes through the high-speed rotating straightening drum for straightening and rust removal. Subsequently, the motor, through another set of reduction belt transmission and a gear reduction box, drives two conveying rollers. One pulls the rebar forward, while the other drives the crank wheel to move the hammer head up and down. When the rebar reaches the preset length, the hammer head strikes the cutter frame, performing a precise cut. After the rebar falls into the material rack, the cutter frame returns to its original position due to spring action, completing the entire straightening and cutting process efficiently.

Unique Advantages of YG Machinery’s Bar Straightening Machine:

- Efficiency Improvement: High degree of automation and a pulling speed of up to 50 meters per minute significantly accelerate rebar processing. High and low speeds can be adjusted according to demand, optimizing cutting efficiency for rebar of varying lengths.

- Quality Assurance: Adopts a double-curve inclined roller design and alloy straightening wheels, reducing wear and ensuring that straightened rebar is free from scratches with minimal strength loss, effectively extending the equipment’s service life.

- Cost-Effectiveness: The hydraulic cutting machine not only saves tool wear but also fundamentally eliminates continuous cutting, effectively reducing short rebar segments and minimizing material waste by up to 20%.

- Innovative Technology: Intelligent PLC control system supports simultaneous input of multiple batches of lengths and quantities (up to 20 batches) and features computer memory storage, offering convenient operation and high accuracy, with a cutting length error of only ±0.5 to 1 cm.

- Stability and Reliability: Stable operation, low failure rate, low noise, and convenient maintenance, providing you with reliable production assurance.

Bar Straightening Machine Q&A

Including steel straightening and cutting function.

The thicker the bar, the faster the speed, e.g. 14mm can reach 65-70m/min.

According to the amount of rebar, the high-speed model of the straightening wheel is made of conventional material. A set of straightening wheels can straighten about 300-500 tons of rebar.

Wide Application Scenarios and Success Stories of the Bar Straightening Machine

The bar straightening machine is widely used in highways, expressways, railways, high-speed railways, bridges, pile foundations, building construction, nuclear power plant projects, and professional rebar processing factories.

Success Story Sharing:

Take Mr. Mohammed, a client from Saudi Arabia, for example. His construction company often faced issues of low straightening efficiency and high scrap rates when processing large quantities of rebar. After integrating YG Machinery’s steel bar straightening machine, Mr. Mohammed reported that their rebar processing efficiency increased by 35%, the scrap rate decreased by 20%, and the overall project delivery time was shortened by 7 days compared to previous processes. He specifically mentioned that our machine’s intelligent PLC control system and high-precision measuring ruler greatly simplified the operation process and ensured the accuracy of every cut.

How to Choose the Right Rebar Straightener?

Selecting a rebar straightener tailored to your needs is critical. You need to consider the rebar diameter range (our equipment can process 4-16mm), production efficiency requirements, and your budget. Additionally, the durability of the equipment, ease of maintenance, and the supplier’s after-sales service are key considerations. Understand the differences in rebar straightening machine price and weigh them against your specific requirements.

Daily Maintenance and Troubleshooting for Your Steel Bar Straightener

To ensure the long-term stable operation of your steel bar straightener, regular maintenance is essential. This includes: regularly lubricating all moving components, checking and tightening loose bolts, and cleaning the equipment’s surface. In case of rebar entanglement or incorrect lengths, our machine also offers convenient solutions: handle rebar ends using the “Disable Cutting” button or correct lengths with the “Length+” / “Length-” buttons, ensuring continuous, uninterrupted production.

Act Now to Get Your Exclusive Bar Straightening Machine Solution!

Still troubled by rebar processing efficiency? Contact YG Machinery now to get your free quote and customize your exclusive bar straightening machine solution!

More YG Machinery products:

- YG Rebar Cutting Machine

- YG Rebar Threading Machine

- YG Rebar Bending Machine

- YG Rebar Stirrup Bender