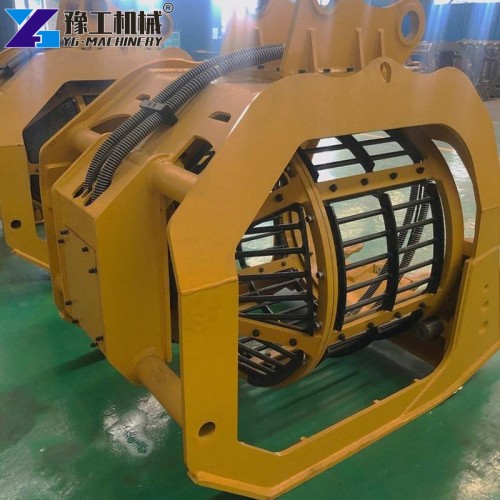

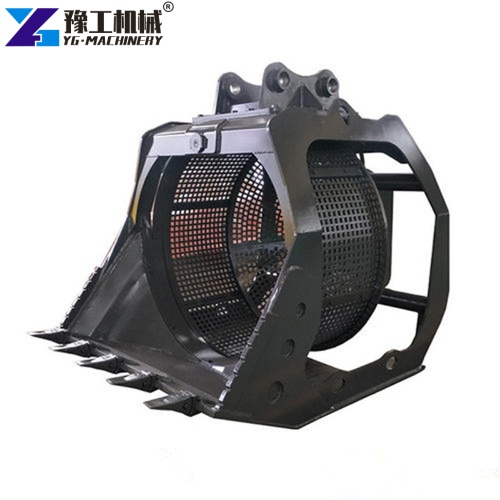

Are you struggling with construction waste disposal or inefficient soil and aggregate screening? The rotary screening bucket – YG’s rotary screening bucket is your ideal solution. It transforms your excavator into a mobile screening plant, significantly streamlining on-site workflows and helping you easily overcome various challenges.

Rotary Screening Bucket Parameter

| Model Number | Applicable Tonnage of Excavator(T) | Operating Flow(L/min) | Working Pressure(Mpa) | Self Weight(Kg) | Number of Revolutions Per Minute(RPM) |

| YG01 | 1.5-3 | 20 | 10-12 | 158 | 35 |

| YG02 | 3.5-5.5 | 30 | 10-12 | 245 | 60 |

| YG08 | 6-10 | 45 | 12-15 | 530 | 65 |

| YG012 | 11-18 | 65 | 15-18 | 1020 | 65 |

| YG016 | 19-28 | 80 | 18-22 | 1920 | 65 |

| YG018 | 29-38 | 150 | 18-22 | 2430 | 65 |

Rotary Screening Bucket: In-Depth Analysis and Technical Advantages

YG’s rotary screening bucket is designed for efficient processing and sorting of bulk materials. Its main purpose is to quickly separate materials of different particle sizes. Whether it’s screening soil, sand, aggregates, construction waste, or compost, it performs with exceptional efficiency.

Core Advantages:

- Efficiency Boost: Integrates screening operations directly into the excavator, eliminating multiple material transfers and the need for separate screening equipment. This significantly shortens operation times and greatly accelerates overall project progress.

- Quality Assurance & Durability: Constructed from high-quality steel, the rotary screening bucket features a robust and stable structure, ensuring high durability and reliability, extending its service life.

- Cost-Effectiveness: Reduces the need for specialized screening equipment, loaders, and additional operators, thereby significantly saving on equipment rental, fuel consumption, and labor costs. It’s more focused on screening than excavator rock crushing buckets, making it more economical for specific material processing.

- Innovative Technology: The rotary screening bucket screens materials through the rotation of the bucket. It features a high-torque, low-speed hydraulic motor with excellent sealing, allowing for underwater operation. Different sieve plate apertures can be easily changed to meet various requirements.

Technical Details:

This equipment typically consists of a trommel screening bucket, motor, reducer, and frame. The excavator screening bucket is installed on the excavator head. A hydraulic motor, via a reducer and coupling, connects to the screening bucket, enabling efficient and continuous material screening.

Extensive Application Scenarios and Industry Cases for Rotary Screening Bucket

YG’s rotary screening bucket has a wide range of applications, making it an ideal choice for various industries.

Key Application Areas:

- Construction and Demolition Waste Treatment: After demolition, it can quickly screen mixed waste like concrete, bricks, and soil, separating recyclable aggregates and inert earthwork.

- Landscaping and Soil Remediation: Before site leveling, it screens soil, peat, compost, and vegetation to produce high-quality garden soil or soil amendments.

- Gravel Pits and Mining Operations: Conducts preliminary screening of excavated sand and gravel to separate aggregates of different particle sizes. For mining projects requiring an excavator rock screening bucket, YG’s product can significantly enhance material processing capabilities.

- Municipal Engineering and Pipeline Laying: Screens backfill soil to ensure uniformity and quality of backfill materials, preventing damage to pipelines.

Success Story:

John, an engineer from Australia, significantly improved waste processing efficiency by 35% and increased the utilization rate of recyclable aggregates by 20% on his demolition project after using YG’s excavator screening bucket for sale. This not only helped his team drastically reduce waste disposal costs but also accelerated project progress, enabling them to complete the task ahead of schedule and within budget. John specifically noted that the convenient installation and intuitive operation of the mini excavator screening bucket allowed their team to quickly get started without complex additional training.

Excavator Bucket Screen Price and Budget Considerations

Many customers consider the excavator bucket screen price when thinking about purchasing a rotary screening bucket. YG is committed to providing cost-effective solutions, ensuring customers get the maximum return on their investment. Factors influencing the price typically include the bucket size, screen drum configuration, and whether customized features are needed. We recommend providing your specific project requirements so we can offer you an accurate quote, ensuring you get the most suitable mini digger screening bucket.

Maintenance and Care Tips for Your Rotary Screening Bucket

To ensure your rotary screening bucket operates efficiently for a long time, proper maintenance and care are crucial. Regularly inspect the screening drum or screen for wear and replace them promptly. Keep the hydraulic system clean and regularly check hydraulic fluid levels and connections. Additionally, clearing residual material from the bucket after each use can effectively extend the equipment’s lifespan. YG provides detailed maintenance guides and professional technical support to help you manage your equipment with ease.

Excavator Attachments for Sale in YG Machinery

Looking for the right tools to boost your excavator’s capabilities? We manufacture a wide range of excavator attachments, each designed for specific tasks and varying specifications. Beyond our rock screening bucket, our selection includes the excavator crusher bucket, hydraulic quick hitch, scrap metal shear, excavator rock saw, excavator pile driver, breaker hammer for excavators, and pile breaker machine, to name a few. Do you need a particular excavator attachment for your next project? Feel free to reach out to us for more detailed information on any of our products.