In the rapidly evolving field of PET plastic bottle manufacturing, choosing a high-performance, high-efficiency blowing machine is crucial. If you’re seeking a competitive PET blowing machine price while ensuring product quality and production efficiency, YG’s range of blowing machines is your ideal choice. Our machines come in various specifications, including single-cavity, double-cavity, and four-cavity models, tailored to your production volume needs. They can produce preforms for salad oil bottles, beverage bottles, wide-mouth jars, cosmetic bottles, pharmaceutical bottles, three-gallon, five-gallon water bottles, and other custom preforms, meeting your diverse production requirements.

PET Blowing Machine Specifications

| Water Bottle Blowing Machine | YG-2L-2 | YG-2L-4 | YG-2L-6 | YG-2L-8 |

| Cavity | 2 | 4 | 6 | 8 |

| Theory output | 2000-2700 | 4000-5000 | 6000-7200 | 8500-9000 |

| Max. volume | 2L | 2L | 2L | 2L |

| Bottle mouth maximum overall diameter | 80mm | 28-38mm | 28-38mm | 28-38mm |

| Bottle biggest diameter | 100mm | 100mm | 100mm | 100mm |

| Bottle maximum height | 330mm | 330mm | 330mm | 330mm |

| Light tube quantity | 16pcs | 40pcs | 64pcs | 32pcs |

| Light tube power | 1.5KW | 1.5KW | 1.5KW | 1.5KW |

| Maximum heating power | 24KW | 40KW | 80KW | 80KW |

| All-electric machine installation | 26KW | 60KW | 85KW | 85KW |

| Actual consumption | 19KW | 30KW | 40KW | 40KW |

| Work pressure | 7-9kg/c㎡ | 7-9kg/c㎡ | 7-9kg/c㎡ | 7-9kg/c㎡ |

| Low-pressure gas consumption | 1000L/min | 1600L/min | 1600L/min | 1600L/min |

| Blow bottle pressure | 25-35kg/c㎡ | 25-35kg/c㎡ | 25-35kg/c㎡ | 25-35kg/c㎡ |

| Higher-pressure gas consumption | 1500Ltr/min | 3000Ltr/min | 4000Ltr/min | 4800Ltr/min |

| Work pressure | 5-6 kg/c㎡ | 5-6 kg/c㎡ | 5-6 kg/c㎡ | 5-6 kg/c㎡ |

| Temperature range | 10℃ | 10℃ | 10℃ | 10℃ |

| Consumption | 5000kcal/hr | 8000kcal/hr | 8000kcal/hr | 12000kcal/hr |

| Frozen water flow | 30L/min | 88L/min | 88L/min | 88L/min |

| Size of the machine | 2.5*1.6*1.7 m | 4.5*2.0*2.3 m | 6.5*2.0*1.9 m | 6.7×2.0×2.3m |

| Weight of the machine | 2.0ton | 4.0ton | 5.5ton | 6.0ton |

YG Blowing Machine: Versatility with a Great PET Blowing Machine Price

YG blowing machines are designed to provide customers with a stable and reliable production experience. Our equipment features a fully automatic human-machine interface, offering intuitive and convenient operation. This ensures stable machine operation, fewer malfunctions, and high blowing speeds. When considering the overall PET blowing machine price, our models offer excellent value due to their low energy consumption, high automation, and simple operation, which effectively reduces long-term production costs.

Structurally, YG blowing machines adopt a modular design, with the oven and slider main body integrated. This simplifies the structure, making daily maintenance more convenient. Furthermore, their unique air circuit design separates the action air from the blowing air, cleverly meeting the different air pressure requirements for blowing and motion, ensuring precise and efficient blowing processes.

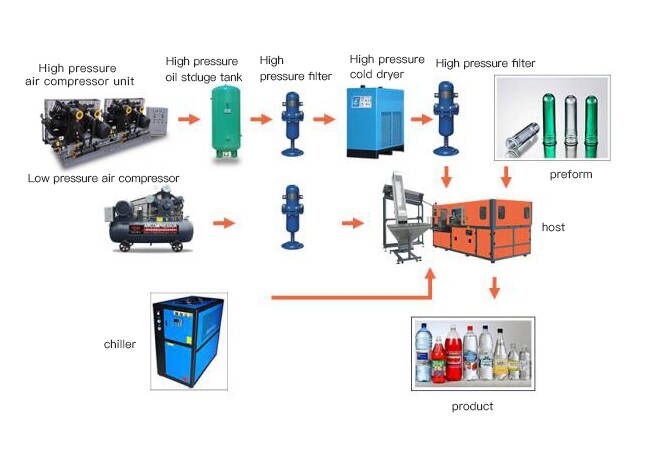

Efficient PET Bottle Production Process and the Value of Your PET Blowing Machine Price

An efficient plastic bottle moulding machine can significantly boost your production output. YG blowing machines feature a highly automated production process, from preform feeding to finished bottle ejection, requiring no manual intervention throughout. The efficiency gained from this automation directly enhances the value you receive for your PET blowing machine price. Its advanced servo system, including traction, clamping, preform loading, and bottle ejection, all utilize Siemens servo systems, ensuring the synchronization and precision of each action.

During production, the machine is equipped with automatic alarm and fault detection functions, capable of quickly identifying and signaling kinetic energy anomalies. This keeps the defect rate at an extremely low level, less than or equal to 0.2%. Such high automation and low scrap rate make YG blowing machines a core component of efficient PET bottle production lines.

Working Principle of Blowing Machines

The working principle of YG blowing machines is primarily based on stretch blow molding technology. Pre-made PET preforms are heated in an oven to reach the appropriate stretching temperature. Subsequently, the heated preforms are transferred into molds. Understanding this precise engineering helps justify the competitive PET blowing machine price we offer. Inside the mold, the preform is blown and expanded by high-pressure air and simultaneously stretched bi-directionally by an axial stretching rod, ultimately forming the desired shape of the PET bottle. The entire process is precisely controlled to ensure uniform wall thickness, high strength, and adherence to strict quality standards. YG’s bottle blow molding machine strictly complies with CE standards, ensuring equipment operational safety and product quality.

Optimizing Your Water Bottle Production Line with an Excellent PET Blowing Machine Price

For businesses involved in large-scale water bottle production, an efficient water bottle blowing machine is indispensable. YG’s blowing machine series, particularly models designed for high-volume demands, can consistently produce high-quality drinking water bottles. The attractive PET blowing machine price combined with their robust performance makes them an ideal investment. We not only offer standard models but also provide customized machine and mold services based on user requirements. This ensures your production line perfectly aligns with market demands, maximizing your production potential.

YG possesses profound technical expertise not only in the blowing machine sector but also is committed to providing customers with comprehensive machinery manufacturing solutions. Our products are exported worldwide, earning the trust of global clients. While our PET blowing machine price is highly competitive, our commitment to quality, service, and custom solutions truly sets us apart. Besides high-quality blowing machines, we offer other machinery such as water bottle filling machines, plastic thermoforming machines, egg tray machines, disposable cup machines, paper bowl machines, paper bag machines, paper making machines, sanitary napkin machines, wet wipe machines, and more. If you are interested in these machines or would like to learn more about our PET blowing machine price and comprehensive solutions, please feel free to contact us!