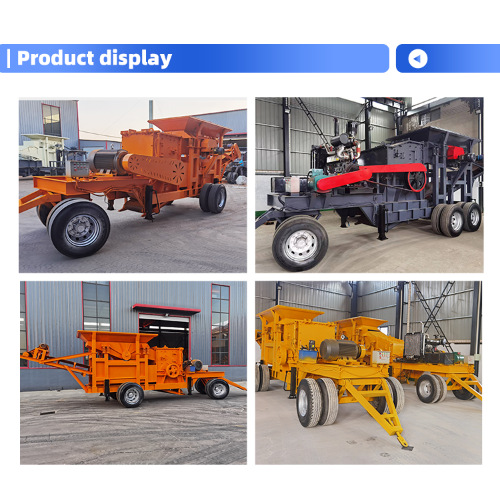

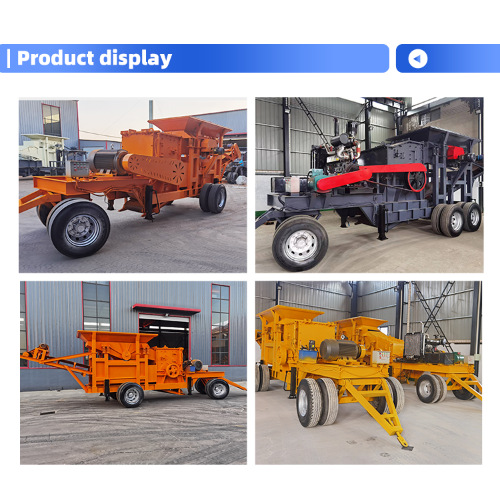

The YG mobile crusher redefines on-site efficiency with its all-in-one design (feeder, jaw crusher, conveyor, control system), enabling rapid deployment in mining, urban construction, and roadbuilding. It handles hard rocks (granite, basalt), tailings, and sticky aggregates, while supporting recycling of construction debris. For compact needs, our small jaw crusher for sale series delivers primary crushing via eccentric shaft-driven jaws, ensuring uniform output and 30% higher throughput with its deep cavity design.【WhatsApp/WeChat/Phone】+86 138 3711 2713

Technical Parameters of Jaw Crusher:

| Model | Feeding Size | Discharging Opening Size | Capacity | Power | Weight | Overall Dimension |

| (mm) | (mm) | (t/h) | (kw) | (t) | (mm) | |

| YG250×400 | ≤210 | 20-60 | 5-21 | 15 | 2.8 | 1300*1090*1270 |

| YG400×600 | ≤340 | 40-100 | 16-64 | 30 | 7 | 1730*1730*1630 |

| YG500×750 | ≤425 | 50-100 | 40-110 | 55 | 12 | 1980*2080*1870 |

| YG600×900 | ≤500 | 65-160 | 50-160 | 55 | 17 | 2190*2206*2300 |

| YG750×1060 | ≤630 | 80-140 | 110-320 | 110 | 29 | 2660*2430*2800 |

| YG900×1200 | ≤750 | 95-165 | 220-380 | 132 | 52 | 3380*2870*3330 |

| YG1000x1200 | ≤850 | 195-265 | 315-500 | 160 | 55 | 3480*2876*3330 |

| YG1200×1500 | ≤1020 | 150-350 | 400-800 | 160-220 | 100.9 | 4200*3300*3500 |

| YG1500×1800 | ≤1200 | 220-350 | 500-1000 | 280-355 | 139 | 5160*3660*4248 |

| YGX150×750 | ≤120 | 18-48 | 8-25 | 15 | 3.8 | 1200*1530*1060 |

| YGX250×750 | ≤210 | 25-60 | 13-35 | 22 | 5.5 | 1380*1750*1540 |

| YGX250×1000 | ≤210 | 25-60 | 16-52 | 30 | 7 | 1560*1950*1390 |

| YGX250×1200 | ≤210 | 25-60 | 20-60 | 37 | 9.7 | 2140*1660*1500 |

| YGX300×1300 | ≤250 | 20-90 | 16-105 | 55 | 15.6 | 2720*1950*1600 |

| YGX500×1500 | ≤3250 | 25-120 | 50-160 | 90 | 20 | 2360*2660*2105 |

Small Jaw Crusher for Sale

The YG small jaw crusher for sale is a rugged heavy-duty crushing machine, primarily used in mining, mineral processing, and construction waste recycling to crush hard rocks efficiently. It integrates a feeder, jaw crusher, belt conveyor, and control system, effectively solving on-site infrastructure challenges.

Applicable Ores: Iron ore, granite, quartz, limestone, pebbles, basalt, etc.

Working Principle: The motor drives the eccentric shaft via a belt pulley, causing the movable jaw to periodically approach and move away from the fixed jaw. This process applies squeezing, rubbing, and grinding forces to the material within the crushing chamber, reducing large particles to smaller ones until they reach the desired size and are discharged from the crusher. The mobile jaw crusher operates on an extrusion principle, utilizing two jaw plates: a fixed jaw and a movable jaw. The movable jaw performs periodic reciprocating movements relative to the fixed jaw, crushing stones through compression and bending. It is primarily used for converting large rocks into medium and small rocks and often serves as a primary crushing unit.

Performance Features:

- Deep crushing chamber with zero dead zones, significantly boosting feeding capacity and output.

- Large crushing ratio and uniform product granularity.

- Special flywheel design reduces vibration for more stable operation.

- Gasket-controlled discharge opening is easy to operate, reduces operating costs, and facilitates inspection and maintenance.

Box Crusher

The box crusher is typically used as a secondary processing unit, often after a jaw crusher. Its structure features a hopper at the top, beneath which a feeder vibrates raw materials into the crushing chamber.

Working Principle: The crusher is driven by a motor or diesel engine, which powers hammers inside the crushing chamber to impact and break stones. Once the material is crushed, it falls onto a screen plate at the bottom of the crushing chamber (usually 5 cm thick manganese steel, with mesh sizes customizable to user requirements for producing sand or gravel). The processed material is then conveyed out by a belt conveyor.

Advantages

- Offers flexible and wide-ranging adjustment of output granularity.

- Minimal wear on vulnerable parts, high metal utilization rate.

- Easy replacement of spare parts, low maintenance costs.

- However, for rocks with high hardness, there may be greater wear and tear on the equipment during the crushing process, which requires the selection of suitable wear-resistant materials and regular maintenance.

Mobile Crusher Jaw Rock Crusher for Sale is Widely Used in The Following Applications:

- Mining Operations: Ideal for primary and secondary crushing of ores like iron ore and granite, greatly improving mining efficiency.

- Coal Mining: For crushing and screening coal in coal production.

- Waste Recycling: Especially for the crushing and recycling of construction waste (e.g., concrete blocks, bricks), promoting environmental resource utilization.

- Earthwork Projects: Crushing earth and stone materials to provide required aggregate sizes for subsequent engineering.

- Urban Infrastructure Development: Performing on-site crushing operations for municipal projects like roads, bridges, and pipelines.

- Road or Construction Sites: Processing materials directly at the construction site, reducing transportation costs and time.

- Processing Topsoil and Various Other Materials: Treating topsoil, construction debris, and other materials for reuse.

- Separating Viscous Concrete Aggregates: Efficiently separating sticky materials to improve aggregate purity.

- Construction and Blasting Industries: For secondary crushing and screening of blasted materials.

- Quarrying Industry: For crushing and processing stones like limestone and basalt to produce various aggregate specifications.

- Artificial Sand Production: Producing high-quality artificial sand from river pebbles, mountain stones (e.g., limestone, granite, basalt, diabase, andesite), ore tailings, and stone chips, especially when looking for a competitive jaw crusher machine price.

Small Jaw Crusher for Sale – YG Machinery Manufacturer

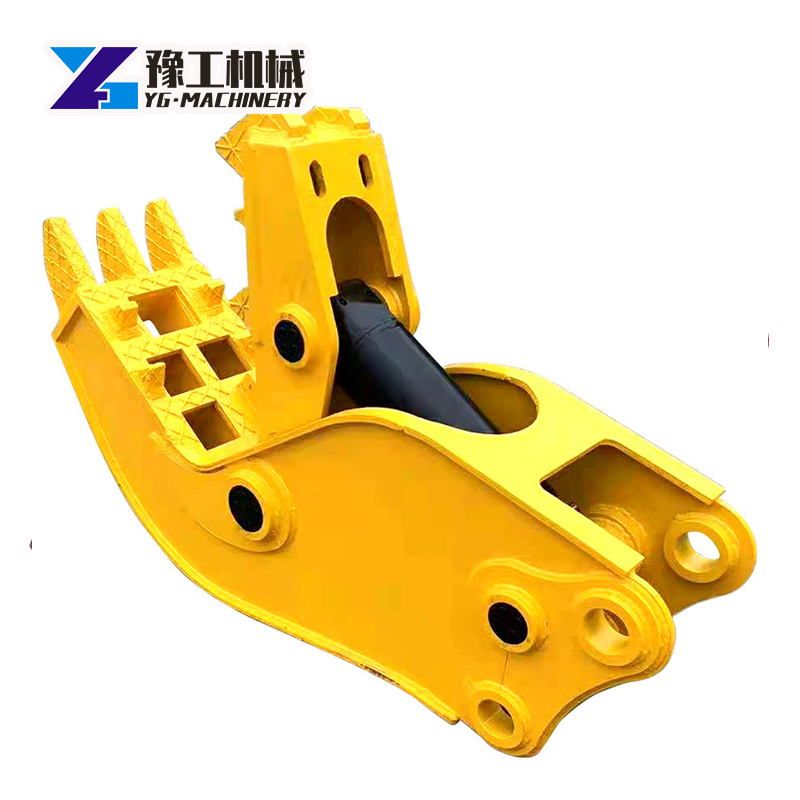

As a professional machinery and equipment manufacturer, YG, we have been deeply engaged in the field of crushing and screening for many years, and are committed to providing high-performance and highly reliable mobile crushing solutions. We understand our customers’ needs for performance and long-term value, so every YG mobile crusher undergoes rigorous quality control and testing to ensure its superior quality. If you’re looking for an efficient, flexible and adaptable mobile crushing plant, whether it’s a small jaw crusher for sale or another model, YG is the ideal choice. Besides mobile crusher, we also have hydraulic cone crusher, mobile crusher, rock crusher, excavator crusher, excavator pile driver, excavator drilling and splitting machine, excavator rock splitter and so on. Contact us for more machine details. 【WhatsApp/WeChat/Phone】+86 138 3711 2713