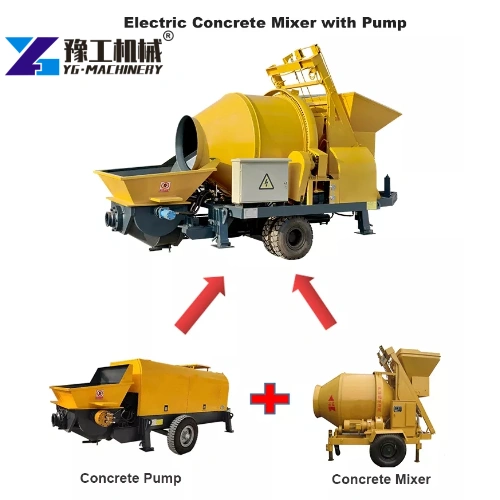

In modern construction engineering, efficiency is the key to success. YG’s concrete mixer pump machine is precisely designed to meet this demand. This innovative equipment cleverly combines a high-performance concrete mixer with a powerful concrete pump. The mixing section is dedicated to efficiently blending various raw materials, ensuring uniform mixing, while the pumping section is responsible for the high-pressure conveying of the mixed materials. Therefore, this is an integrated device for both mixing and high-pressure pumping, capable of significantly improving construction efficiency. It is particularly suitable for conveying lime mortar, fine aggregate concrete, and more, making it an ideal choice for various construction projects.【WhatsApp/WeChat/Phone】+86 138 3711 2713

Concrete Mixer Pump Machine Parameter

| Model | YG350 | YG400 | YG500 | YG750 | |

| Working performance | Discharge capacity | 350L | 400L | 500L | 750L |

| Feed capacity | 560L | 650L | 800L | 1200L | |

| Productivity | 10-14m3/h | 18-28m3/h | 14-18m3/h | 20-22m3/h | |

| Speed | 14r/min | 14r/min | 13r/min | 13r/min | |

| Maximum aggregate size | 60mm | 60mm | 60-80mm | 60-80mm | |

| Motor | Stirring motor | 5.5KW | 7.5KW | 11KW | 15KW |

| listing motor | 5.5KW | 7.5KW | 5.5KW | 7.5KW | |

| Pump motor | 0.55KW | 0.75KW | 0.75KW | 1.1KW | |

| Dimension | 2766*2140*3000mm | 3850*2200* 2850mm | 5226*2200* 5460mm | 6116*2056* 6060mm | |

| Total weight | 1950kg | 1950kg | 3100kg | 4200kg | |

Concrete Mixer Pump Applications

- High-rise buildings: transport concrete to floors, columns, and other parts of high-rise buildings to improve construction efficiency. Secondary structural column grouting, foundation reinforcement.

- Bridges and tunnels: transport concrete to narrow and difficult-to-reach construction areas in bridges, tunnels, and other projects.

- Hydraulic projects: used for concrete pouring in dams, levees, and other hydraulic projects.

- Underground projects: transport concrete to underground spaces in basements, subways, and other projects.

- Other projects: suitable for various projects that require large-scale concrete pouring, such as roads, airports, ports, etc.

Advantages of Concrete Mixer With Pump

- 4- 6X Faster: Simultaneous mixing and pumping slash project timelines.

- Compact & Mobile: Perfect for confined spaces like basements or tunnels, with rapid deployment between sites.

- High Power: The equipment’s power system, hydraulic system, and pumping system are reasonably matched to maximize the motor’s power.

- Long Service Life: The smooth S-pipe valve reversing can accommodate the conveyance of fine concrete or commercial fine stone concrete, and it is not easy to block the pipe, prolonging the service life of the S-pipe.

- Flexible Operation: A variety of vehicle models, such as vehicle-mounted, trailer-mounted, and static types, are suitable for different construction environments. The boom can be flexibly rotated to achieve multi-angle transportation to meet complex construction needs.

- High Degree of Automation: Adopts an advanced hydraulic system and control system, self-diagnosis of faults, easy operation, and high efficiency.

- Customized Service: Provides customized solutions according to customer needs.

Concrete Mixer With Pump Manufacturer – YG Machinery

YG has exported over 300 concrete mixers and pump units to countries including Mexico, Nigeria, and Australia. Our portfolio also includes:

- Comprehensive Equipment: Mini concrete pumps, shotcrete machines, scissor lifts, and more.

- Tailored Solutions: Customize pump pressure, mixing capacity, and receive end-to-end technical support.

Looking for a concrete mixer pump for sale or other construction machinery? Contact YG today for pricing, specifications, and success stories from global clients.【WhatsApp/WeChat/Phone】+86 138 3711 2713