Want to build a house but worried? High costs, long timelines, and mismatched sites are common problems—whether you need guesthouses by Australia’s coast or temporary classrooms on Philippine islands, traditional construction can’t fix them. But the 40ft expandable container house is the solution: it folds to expand space, works for both temporary and permanent use; most parts are pre-made in the factory, so installation takes 2/3 less time than traditional buildings, and it costs over 30% less. It works in many places around the world.

40ft Expandable Container House Parameter:

| 20FT Basic Characteristics | External dimension (mm) | W6320*L5900*H2480(Side 2270) |

| Internal dimension (mm) | W6160*L5560*H2240(Side 2150) | |

| Folded state (mm) | W2200*L5900*H2480 | |

| Total mass (kg) | 2500 | |

| 30FT Basic Characteristics | External dimension (mm) | W6360*L9000*H2480(Side 2180) |

| Internal dimension (mm) | W6200*L8660*H2240(Side 2060) | |

| Folded state (mm) | W2200*L9000*H2480 | |

| Total mass (kg) | 3750 | |

| 40FT Basic Characteristics | External dimension (mm) | W6240*L11800*H2480(Side2180) |

| Internal dimension (mm) | W6080*L11540*H2200(Side2060) | |

| Folded state (mm) | W2200*L11800*H2480 | |

| Total mass (kg) | 4400 | |

| Smaller Fold Size | External dimension (mm) | W4820*L5900*H2480(Side2270) |

| Internal dimension (mm) | W4660*L5560*H2240(Side2150) | |

| Folded state (mm) | W700*L5900*H2480 | |

| Total mass (kg) | 1850 |

40ft Expandable Container House: Technical Advantages for Multi-Regional Needs

Core Product Features

- Space Expansion Mechanism: Hydraulic/mechanical folding design, accommodating 2-6 people, suitable for families, camps, and other scenarios.

- Fully Prefabricated Production: 95% of components are assembled in the factory; 4 workers can complete on-site installation in 1 hour, reducing construction disturbance and material waste, ideal for projects with tight schedules in various regions.

- Multi-Climate Adaptability: Integrates water and electricity systems with thermal insulation, resisting 120km/h strong winds and 250kg/m² roof loads; usable in extreme climates from -30℃ to 50℃, covering cold, tropical, and other regions.

Core Product Advantages

- Efficiency Improvement: Compared with traditional brick-concrete structures, the construction cycle is shortened by 70%, especially suitable for post-disaster reconstruction and emergency accommodation scenarios.

- Quality Assurance: Galvanized steel frame + PU sandwich panels, service life exceeding 20 years; structural stability verified by tests in multiple regions.

- Cost-Effectiveness: Comprehensive costs are 30-50% lower than traditional buildings; energy-saving and thermal insulation design reduces long-term energy consumption by 20%, lowering regional operation costs.

- Innovative Technology: Patented folding hinges certified by CE; modular water and electricity interfaces enable “plug-and-play” installation, adapting to infrastructure standards in most global regions.

40ft Expandable Container House FAQ

The product has passed 120km/h wind resistance and 8-level seismic tests, and has been applied in complex environments such as Australia’s coast, the U.S. Midwest, and the Philippines’ islands. Solar panels and rainwater harvesting systems can be optionally installed on the roof, making it usable in off-grid regions.

Supports 1-4 bedrooms, open kitchens, wet-dry separated bathrooms, and other plans. For example, 3 bed 2 bath container home can be customized for multi-person families; 30ft expandable container home is suitable for small sites, adapting to spatial needs in different regions.

One unit can be loaded into a 40HQ container; transportation costs are 40% lower than traditional building materials. The factory provides bilingual installation manuals and video tutorials; remote guidance is sufficient for operation, no additional regional on-site service costs required.

40ft Expandable Container House: Global Application Scenarios

Application Field Expansion

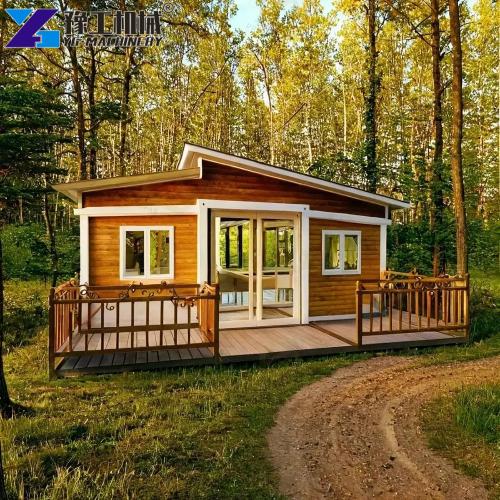

- Tourism Accommodation: Homestays in Queenstown, New Zealand use it as featured rooms; panoramic windows + terraces enhance the landscape experience, with occupancy rates 25% higher than traditional rooms; some small homestays choose 20ft expandable container house for narrow sites.

- Mining Camps: An Australian iron ore project used 50 units to build worker dormitories, completing accommodation for 1,000 people in 2 weeks—60% faster than traditional prefabricated houses, adapting to the rapid infrastructure needs of remote mining areas.

- Education & Healthcare: A Philippine island school used it to build temporary classrooms, which can be quickly stored during typhoon seasons to protect equipment; some campuses match it with container foldable house as infirmaries, flexibly utilizing regional space.

Success Case

Australian customer James operates a tourist resort in Queensland. The original wooden houses had high expansion costs and long cycles, making it difficult to meet peak-season demand. After adopting YG Machinery’s 40ft expandable container house, the number of guest rooms increased by 50% within 3 months—panoramic glass walls and rooftop terraces attracted family tourists, with peak-season occupancy reaching 92%. He also customized 2 bedroom 40ft container home to meet family customer needs, shortening the investment payback period to 8 months, perfectly adapting to local tourism market demands.

40ft Expandable Container House Installation Guide

Four-Step Standard Process (Adapting to Sites in Most Global Regions)

- Foundation Preparation: Level the site and pour concrete foundations, reserve water and electricity interfaces; the simple process adapts to infrastructure conditions in different regions.

- Structure Expansion: Hoist the main body with a crane, expand side walls via hydraulic rods, no complex equipment required.

- System Connection: Connect pre-installed water/electric pipelines and circuit modules; complete functional testing within 2 hours, “plug-and-play” adapting to standards in multiple regions.

- Interior Installation: Optional finished furniture and smart devices enable “move-in ready” occupancy, meeting living habits in different regions.

40ft Expandable Container House Customization: Adapting to Regional Living Needs

Three Customization Dimensions (Fitting Regional Characteristics)

- Space Layout: Supports open-plan, LOFT, duplex, and other structures; for example, 3 bed 2 bath container home can adjust the ratio of public and private areas, adapting to multi-person families; 10ft expandable container home is suitable for small independent use, adapting to spaces in cities, villages, and other regions.

- Exterior Design: More than 10 exterior materials (PVC cladding, cement wood grain panels, etc.) + asphalt shingle/metal roofs, matching local architectural styles to avoid regional aesthetic conflicts.

- Smart Systems: Optional solar power supply, underfloor heating, and fresh air systems; enhanced insulation for cold regions and optimized ventilation for tropical regions, adapting to climate in different regions.

Customization Service Process

- Within 72 hours of submitting requirements, 3D design proposals and quotes are provided, with details adjusted according to regional needs.

- Production cycle is only 25 working days, supporting small-batch trial production and urgent orders, adapting to the schedule requirements of regional projects.

Customer Testimonial (Feedback from Regional Users)

“YG Machinery’s 40ft expandable container house solved our accommodation problem in Canadian mining areas—we completed a 50-person camp in 2 weeks, and the winter insulation effect exceeded expectations, saving a lot of energy costs compared to traditional prefabricated houses.” — Michael Johnson, Canadian Mining Project Manager.

Consult Now: Get Exclusive Regional Adaptation Plan for 40ft Expandable Container House