In Malaysia’s residential construction market, contractors often struggle to balance cost and efficiency. When Mr. Amir, a housing contractor in Selangor, started several villa foundation projects, he realized his old concrete pouring process consumed too much labor and time. He began searching online for a reasonable concrete mixer pump price that could meet his workload without exceeding budget.

After comparing several suppliers, he contacted YG Machinery because of its transparent quotation and detailed technical consultation. Rather than just sending a number, YG explained how concrete mixer pump price depends on engine type, delivery distance, output capacity, and after-sales service. This price transparency built instant trust and led to an order for a diesel concrete mixer with pump.

What Factors Determine Concrete Mixer Pump Price

Before deciding, Amir wanted to understand what really drives concrete mixer pump price differences in the market. YG’s technical manager summarized it in four main factors:

- Power Source – Diesel models tend to be a bit pricier than electric versions, but they save on fuel and eliminate power limitations.

- Pumping Capacity – A machine with a capacity of 30 m³/h is generally less expensive than one with a capacity between 40 and 50 m³/h.

- Setup – Components like hydraulic systems, durable pipes, and high-pressure cylinders influence both the longevity and overall cost.

- Service and Delivery – Certain suppliers offer low prices for concrete mixer pumps but do not include shipping, training, or warranty in the cost.

By analyzing these cost elements, Amir was able to understand why two machines that appear alike online could have price differences of several thousand dollars.

| Technical parameters | ||

| Maximum Theoretical Concrete Mixing | M³/h | 15 |

| Maximum Theoretical Concrete Output | M³/h | 30 or 40 |

| Theoretical maximum transmission distance | m | Vertical 50/Horizontal 200 |

| Distribution Valve Form | S valve | |

| Hopper Volume*Height | L*mm | 600×1080 |

| Pumping Motor Power | KW | 30 or 45 |

| Winch Motor Power | KW | 5.5 |

| Hydraulic Oil Form | open circuit | |

| Rated Speed | rpm | 1480 |

| Fuel Tank Capacity | L | 170 |

| Weight | kgs | 3500 |

| Concrete Delivery Pressure | Mpa | 6 |

| Concrete Cylinder Specification*Stroke | mm | φ180 * 800 or 200 * 800 |

| Spout Diameter | mm | φ180 |

| Mixing Motor Power | KW | 8 or 4 |

| Pump Motor Power | W | 550 |

| Maximum Aggregate Size | mm | Grait:40MM; Gravel:30MM |

| Voltage | V | 380 |

| Dimensions (L * W * H) | mm | 4200x2100x3300 |

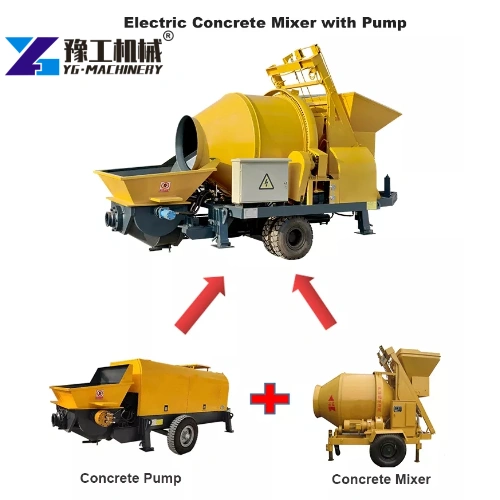

YG’s Diesel Concrete Mixer with Pump: The Price-to-Performance Balance

After careful comparison, Amir selected YG’s diesel concrete mixer with pump, a 30 m³/h model designed for small and mid-size housing projects. The offered concrete mixer pump price included:

- Complete pumping system featuring a 160-cylinder hydraulic booster

- Free operator training available through video or in-person sessions

- One-year warranty along with a spare parts package

- Delivery to Port Klang on a CIF basis

Although some brands offered lower prices for mini concrete pumps, YG’s quote transparently included all necessary components with no hidden charges. When factoring in savings on labor and fuel, the unit provided a better cost-to-performance ratio. It represented the perfect balance of affordability and dependability for villa and small commercial projects.

How Transparent Pricing Builds Trust

Unlike some suppliers who only show the base concrete mixer pump price, YG Machinery emphasized the total cost of ownership (TCO). This includes not only the machine price but also maintenance, fuel, and spare parts. The sales team shared a comparison chart of five popular models, showing lifetime cost differences under real working hours.

This helped Amir realize that a slightly higher concrete mixer pump price at the beginning can actually lower expenses over time—because durable components, stable pressure, and fewer breakdowns mean fewer delays and less labor cost. YG’s pricing philosophy was clear: “Don’t sell cheap, sell right.”

Real Construction Use: Price Reflected in Performance

Upon arrival, the YG diesel pump quickly proved its worth. At the Johor site, the team utilized it for pouring villa floor slabs and building retaining walls. The combined cement mixer and pump allowed the crew size to be halved from 8 to 4 workers, while maintaining a steady flow rate of 30 cubic meters per hour.

Fuel consumption also stayed within the planned budget. Compared to renting older machinery, the overall cost per cubic meter of concrete decreased by 25%. This validated that YG’s concrete mixer pump pricing was not only competitive but also a financially wise choice.

Comparing YG to Other Brands on Price and Service

In Malaysia’s current market, a standard concrete mixer pump price ranges between USD 18,000–32,000, depending on specifications. Some imported brands price above USD 35,000 but require long delivery times and complex maintenance.

YG Machinery’s pricing falls in the middle range but includes faster delivery, flexible payment options, and localized service. Contractors like Amir found that the “real” concrete mixer pump price—after accounting for downtime and logistics—was significantly lower with YG.

Technical Highlights Behind the Price

YG’s model uses a hydraulic-driven system and adopts wear-resistant S-pipe distribution, imported seal rings, and smart pressure control. These features explain why its concrete mixer pump price may differ slightly from low-end market options.

Every part is chosen to optimize both cost and durability. The sturdy 160-cylinder guarantees reliable operation over pumping distances of 100–120 meters, making the investment valuable for extended projects. Buyers receive more than just machinery—they gain stability, lower maintenance needs, and trusted brand quality.

The Role of After-Sales Support in Real Value

Another often-ignored part of concrete mixer pump price is after-sales support. YG’s dedicated team provided bilingual instruction manuals, spare parts, and 24-hour technical response. For Amir, this service meant fewer uncertainties and smoother project planning.

As he said: “The support I got from YG made the concrete mixer pump price feel even more reasonable. When a machine earns money from day one, price becomes secondary.”

Market Trend: Growing Demand in Southeast Asia

Malaysia, Indonesia, and the Philippines are seeing rising demand for small-scale portable concrete mixer pump models. Diesel variants dominate rural construction where electric supply is unstable. Buyers are becoming more informed—no longer chasing the lowest concrete mixer pump price, but focusing on total lifecycle cost and ROI.

YG Machinery positions itself exactly in this market segment—providing high-efficiency, affordable, and well-supported solutions to help local contractors scale faster.

Conclusion: Choose the Right Price, Not Just the Lowest

The story of Mr. Amir’s villa project shows that the concrete mixer pump price is not only about numbers—it’s about value. Transparent quotation, full configuration, and reliable after-sales define the real worth of a product.

Whether you are building houses, villas, or small industrial sites, YG Machinery can help you find the right model at a fair concrete mixer pump price.

👉 Contact YG today for a free quotation and see how much time, money, and manpower you can save on your next concrete project.