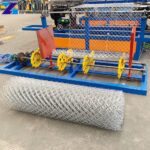

Are you also struggling with low manual fencing production efficiency and missed deadlines? Canadian client Mark faced this exact problem—until he chose YG’s chain link fencing machine. This machine not only helped him complete a big municipal order but also boosted his production profit by 30%. Next, let’s see how wire mesh making machines transformed his business.

Why Mark Needed a Reliable Chain Link Fencing Machine

Client Overview: Mark’s Municipal Fencing Dilemma

Mark runs a municipal fencing installation business in Ontario, Canada, focusing on road barriers and park protection projects. In 2023, he won a bid for the local government’s “Road Safety Upgrade Program,” requiring 15,000㎡ of chain link fencing to be delivered in 3 months.

But back then, he only used traditional semi-automatic equipment, producing just 50㎡ per day with 5 workers taking turns. Not only was efficiency low, but manual errors often made the substandard mesh. With the deadline approaching, Mark urgently needed an efficient chain link fencing machine.

Core Pain Points: Triple Pressure from Efficiency, Cost, and Quality

- Low efficiency: Traditional equipment only produced 8-10㎡ per hour, far from meeting the 15,000㎡ deadline;

- High costs: The 5 workers’ daily wages totaled about 1,200 CAD, with labor costs accounting for 40%;

- Unstable quality: Manual wire feeding caused uneven link sizes, leading to an 8% customer rejection rate.

- Mark said: “I contacted 3 suppliers, and only YG’s wire mesh making machines could solve all three problems.”

Chain Link Fencing Machine Parameter:

| Model | YG-20-100 | YG-25-80 |

| Wire diameter | 1.3-4mm | 2-4mm |

| Mesh size | 20-100mm | 25-100mm |

| Mesh width | 0.5-4m | 0.5-4m |

| Speed | 70-80m²/h | 120-180m²/h |

| Mesh length | 30m, adjustable freely as promised | |

| Mesh side | Knuckled and twisted, or knuckle, or twisted | |

| Raw material | Galvanized wire, PVC-coated wire, etc. | |

| Machine size | 4.2*2.2*1.7m | 6.7*1.43*1.8m |

| Weight | 2000kg | 4200kg |

| Note: We can customize the machine according to your specific requirements for wire diameter, mesh hole size, mesh width, and voltage (default compatible with 220V/380V universal voltage, customizable for regional voltages like Canada’s 120V/240V). | ||

YG Chain Link Fencing Machine: A Custom Solution for Mark

Equipment Parameters: Perfectly Matching Municipal Project Needs

- Mark’s project required 2.5mm diameter steel wire and 1.8m wide mesh—YG’s wire mesh making machines fit perfectly:

- Production speed: 120㎡ per hour, 12 times faster than traditional equipment;

- Wire compatibility: Supports 2-6mm diameter, no frequent parameter adjustments;

- Mesh width: Freely adjustable from 1-3m, exactly matching the project’s 1.8m requirement;

- Automation level: Fully automatic from wire feeding, forming to cutting, no full-time professional operator needed.

- “When I saw the equipment parameters, I knew this was what I needed,” Mark recalled. “It perfectly fits my project requirements.”

YG’s Services: Full Support from Consultation to Production

- Pre-sales consultation: YG engineers calculated the optimal configuration of “1 chain link fencing machine + 2 workers” based on project area and deadline, avoiding equipment waste; The 2 workers only need to be responsible for auxiliary tasks such as raw material loading and finished product winding, no professional skills required;

- Technical support: After equipment delivery, YG provided remote installation guidance and detailed operation videos—Mark’s workers learned to use it in 1 day;

- After-sales response: Once the machine had a small fault, Mark contacted YG in the early morning, and engineers solved it via video in 1 hour, no production delays.

- Customization process: The customization cycle is 7-15 working days, with no additional design fees. The communication process is: requirement confirmation → scheme design → production and manufacturing → logistics delivery.

Actual Results of Chain Link Fencing Machine: Numbers Speak

Doubled Production Efficiency, Deadline Met Early

With YG’s wire mesh making machines, Mark’s daily output jumped from 50㎡ to 180㎡. The 3-month project was completed in 2.5 months. He even delivered 10% extra mesh ahead of time, earning an additional reward from the government. This case is shared after two years of continuous and stable operation of the equipment, which fully verifies the durability and reliability of the product.

Costs Cut Sharply, Profits Raised

- Labor costs: Workers reduced from 5 to 2, saving 720 CAD per day—nearly 50,000 CAD total for the project; 720 CAD/day × 75 days (actual project duration) = nearly 54,000 CAD total for the project;

- Material waste: Mesh qualification rate rose from 92% to 99.5%, cutting steel wire waste by 75%, saving about 30,000 CAD in material costs;

- Profit change: Thanks to reduced labor and material costs, plus additional income from early delivery rewards, the project profit increased from 15% to 45%.

Mark smiled and said: “This chain link fencing machine is my ‘money-maker’—it paid for itself in 6 months.”

Client Feedback: A “Great Machine” Recommended to Peers

After 1 month of operation, the client’s production manager shared: “YG’s mesh welding machine has completely transformed our workflow — we now meet 100% of our monthly orders on time. We’re already in talks to purchase YG’s chain link fencing machine next quarter, as it will let us offer one-stop fencing solutions to our customers, from mesh to finished chain link fences.”

YG Chain Link Fencing Machine Global Market: More Than Canada, Trusted Worldwide

YG’s wire mesh making machines is not only popular in Canada but also sold to over 20 countries including the US, Australia, South Africa, and Germany—these countries have high demand for chain link fencing in municipal, agricultural, and warehousing industries.

For example, clients in California (US) use it to produce farm fencing and have purchased 3 units consecutively; clients in Australia use it for sports venue fencing projects, and the equipment has been operating continuously for 18 months without major failures. Both feedback “high efficiency and strong stability.” This is because YG’s chain link fencing machine can be fine-tuned based on steel wire specs and project needs in different countries, with far better adaptability than similar products.

Boost Your Fencing Production Efficiency with Chain Link Fencing Machine

If you’re like Mark—troubled by low production efficiency and high costs—try YG’s chain link fencing machine. It not only helps you meet order deadlines on time but also cuts costs and raises profits. Contact YG now to get a custom solution and start efficient production.