Canada, as a key economic player in North America, continues to see growth in infrastructure development and energy projects, driving strong demand for efficient and environmentally friendly underground construction technologies. The North American Horizontal Directional Drilling (HDD) market is projected to account for 36.8% of the global revenue share by 2037 , fueled by significant investments in infrastructure upgrades, oil and gas extraction, and clean energy initiatives. Against this backdrop, the demand for high-performance directional drilling machine for sale is increasing, providing YG with a broad market. YG offers advanced horizontal directional drilling machines to meet the Canadian market’s need for precise and efficient underground construction solutions.

Directional Drilling Machine for Sale Parameter:

| Model | YG-160A | YG-180 | YG-280 | YG-320 | YG-320A |

| Engine rated power | 100KW | 97KW | 160KW | 140KW/160KW | 160KW |

| Push and pull | Cylinder | Motor | Motor | Cylinder | Motor |

| Maximum drag/feed force | 160/100KN | 180/180KN | 280/280KN | 320/320KN | 320/320KN |

| The maximum torque of the powerhead | 5000N.n | 6000N.n | 10000N.n | 12000N.n | 12000N.n |

| Powerhead speed | 0-180r/min | 0-140r/min | 0-120r/min | 0-140r/min | 0-140r/min |

| Moving speed of powerhead | 30m/min | 20m/min | 20m/min | 20m/min | 20m/min |

| Maximum reaming hole diameter | Φ600mm | Φ600mm | Φ750mm | Φ800mm | Φ800mm |

| Drill rod length (single) | 3m | 3m | 3m | 3m | 3m |

| Drill pipe diameter | Φ60mm | Φ60mm | Φ73mm | Φ73mm | Φ73mm |

| Drill pipe diameter | 10-23° | 10-22° | 10-23° | 10-20° | 10-20° |

| Maximum mudflow | 160L/min | 250L/min | 320L/min | 320L/min | 320L/min |

| Maximum mud pressure | 100bar | 80bar | 80bar | 80bar | 80bar |

| Overall quality | 6700kg | 8500kg | 12500kg | 11500kg | 11200kg |

| Dimension(length*width*height) | 5700*1820*2400mm | 6400*2270*2340mm | 7100*2260*2450mm | 7100*2250*2450mm | 7662*2162*2450mm |

YG Directional Drilling Machine for Sale: A Canadian Client’s Purchase Journey

Recently, a well-known utility contractor from Alberta, Canada, decided to invest in a state-of-the-art horizontal directional drilling machine. This move comes as a response to the increasing demand for expanding local energy pipeline networks. The contractor specializes in underground pipeline installation for both urban and industrial settings, where performance, reliability, and solid supplier support are crucial. After thoroughly evaluating various options for directional drilling machines available on the market, they ultimately opted for a large-scale horizontal directional drilling machine from YG.

YG Directional Drilling Equipment: Project Background and Client Application

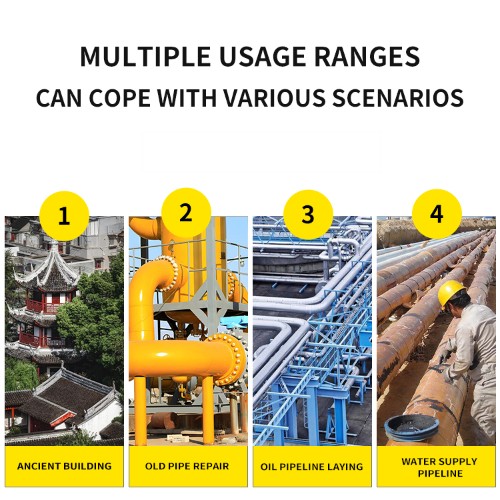

The main project for our Canadian client was all about installing a new natural gas transmission pipeline in a suburban part of Alberta. This involved crossing several farmlands and a small river. The challenge was to lay the pipeline over a long distance while keeping the surface vegetation and river ecosystems undisturbed. To tackle this, the client turned to YG’s directional drilling equipment, which allowed them to carefully drill a pilot bore, ream it out, and then pull the natural gas pipeline into position. The smart auxiliary system on YG’s drill was key in managing the drilling depth and bending radius, ensuring that the pipeline was installed accurately, especially when it came to crossing under the river.

YG Horizontal Drilling Machine for Sale: Client Feedback

The client shared that YG’s directional drilling machine, with its high and low-speed push-pull rotation system, really enhanced the drill rod’s ability to adapt to different soil conditions. It managed to keep drilling speeds steady, even when hitting tough patches of hard soil. Thanks to the digital instrumentation and electronic sensing technology, operators could keep an eye on drilling parameters in real-time, which made the whole construction process more convenient, safe, and efficient. The project manager from the client’s side remarked: “YG’s horizontal directional drilling machine went above and beyond our expectations. Its performance was impressively stable, particularly in the tricky river crossing area. The machine’s precise control and robust hydraulic system helped us finish our project on schedule while minimizing environmental impact. We were also really pleased with the thorough service from YG; from choosing the right equipment to providing on-site guidance, their team was incredibly professional, which gives us a lot of confidence for future projects together.”

Choosing YG HDD Boring Machine: Quality and Comprehensive Service

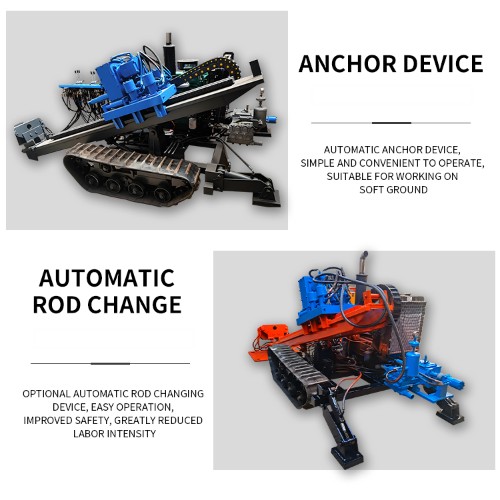

The Canadian client decided on YG’s HDD boring machine because they trust the quality of YG’s products and their all-around service. YG’s drilling machines are equipped with cutting-edge technologies, like a closed-loop energy-saving circuit and electro-hydraulic proportional control, which guarantee both efficiency and reliability. Plus, YG goes beyond just providing top-notch equipment; offers complete solutions for its clients. This includes everything from pre-sales consultations and technical support to after-sales service.

If you’re on the lookout for a top-notch horizontal directional drilling machine or want to explore our range of directional drilling machines for sale, we warmly invite you to reach out to YG Machinery. Our dedicated team is here to offer you the most precise quotes and the best procurement solutions tailored just for you.