Are you looking for a mesh welding machine that can genuinely boost your production efficiency and product quality? Are you tired of inefficient equipment and inconsistent products? One of our clients from the US market, Mr. Jackson, faced these very challenges. How did he completely transform his company’s production model with a solution from YG? This story has the answer for you.

Mr. Jackson’s Dilemma: Outdated Equipment and Production Bottlenecks

Mr. Jackson runs a business in the US that specializes in security and construction mesh. His factory has years of production experience, but it faced a growing problem: aging equipment led to low production efficiency and significant product quality fluctuations. Every time a large order came in, he felt immense pressure, unable to guarantee timely and accurate delivery.

He urgently needed a new mesh welding machine. This machine not only had to be stable but also needed to feature automation to reduce labor costs and improve production precision. He had also considered other equipment, such as a chain link fence machine, but ultimately decided to focus on welded mesh, as it was his company’s core business.

Mmesh Welding Machine Parameter:

| Model | YG-20-100 | YG-25-80 |

| Wire diameter | 1.3-4mm | 2-4mm |

| Mesh size | 20-100mm | 25-100mm |

| Mesh width | 0.5-4m | 0.5-4m |

| Speed | 70-80m²/h | 120-180m²/h |

| Mesh length | 30m, adjustable freely as promised | |

| Mesh side | Knuckled and twisted, or knuckle, or twisted | |

| Raw material | Galvanized wire, PVC-coated wire, etc. | |

| Machine size | 4.2*2.2*1.7m | 6.7*1.43*1.8m |

| Weight | 2000kg | 4200kg |

| We can design the machine according to your wire diameter, mesh hole size, mesh width, and voltage. | ||

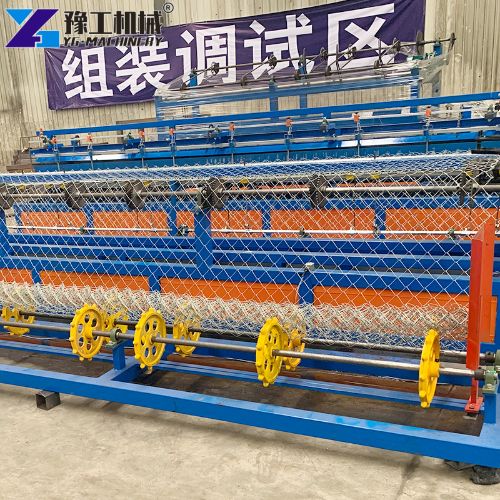

YG’s Solution: A Custom-Made Mesh Welding Machine

After thorough research, Mr. Jackson found YG Machinery. He shared his pain points and his specific requirements for the new equipment:

- High Automation: The machine needed to automatically feed, weld, and cut.

- High Precision: The mesh size had to be precise, and the weld spots needed to be firm.

- Reliability: The machine had to run stably for long periods, reducing downtime.

Our engineering team immediately got to work, providing him with a detailed, customized solution. Our wire mesh welding machines perfectly matched his needs. We showed him the detailed technical specifications of our equipment, such as:

- Servo Control System: This ensures every step is precise and accurate.

- High-Strength Weld Spots: This guarantees a durable and sturdy mesh structure.

- Remote Diagnostic Function: This makes it easy for us to provide remote technical support.

Why Choose YG? It’s More Than Just a Mesh Welding Machine

Mr. Jackson chose us not only because of our excellent equipment performance. More importantly, the comprehensive service we offered gave him peace of mind.

- Professional Consultation: From the initial inquiry to the final solution, we provided expert guidance.

- Customization: We adjusted the machine’s parameters based on his factory layout and specific needs.

- Remote Support: Our team assisted him with the machine’s installation and initial debugging through video calls and detailed operational guides.

He also learned that YG’s mesh welding machine had been sold to many countries worldwide, including major markets like the US, Australia, and the Middle East. This further solidified his confidence in us.

Results: A Double Leap in Production Efficiency and Quality

After the equipment was put into use, Mr. Jackson’s factory underwent a complete transformation.

- Efficiency Boost: Production speed increased by nearly 80%, significantly shortening delivery times.

- Consistent Quality: The mesh quality fully met his clients’ standards, with a near-zero defect rate.

- Reduced Costs: Automated production reduced the reliance on manual labor, leading to lower operating costs.

Mr. Jackson excitedly said, “YG’s mesh welding machine is the best investment my factory has ever made. The machine runs very stably, and the YG team is always there to help when I need them. This machine has changed our business.”

Mr. Jackson’s success story is just one of many for YG around the globe. Our mesh welding machine has helped clients worldwide achieve significant leaps in production efficiency, earning a strong market presence.