If you develop tourism or camp projects in the US, do you often struggle with the “slowness” and “high costs” of traditional construction? Construction took over 3 months, costs exceeded the budget by 40%, and it was hard to adapt to mountain or coastal sites? Mike in California once faced these issues, but 40ft expandable container house USA not only solved his problems but also made the project profitable ahead of schedule—this case will show you how this product becomes a top accommodation solution in the US market.

Mike’s Dilemma: California Mountain Resort Stuck on Guest Room Deadlines

Mike runs a mountain resort in Northern California. In 2023, he planned to add 20 guest rooms for the summer tourist season. But the traditional wooden house plan troubled him: first, the 4-month construction period would miss the peak season; second, transporting materials to the mountain was costly, pushing the total budget over by 35%; third, local environmental requirements were strict, making traditional construction prone to violations.

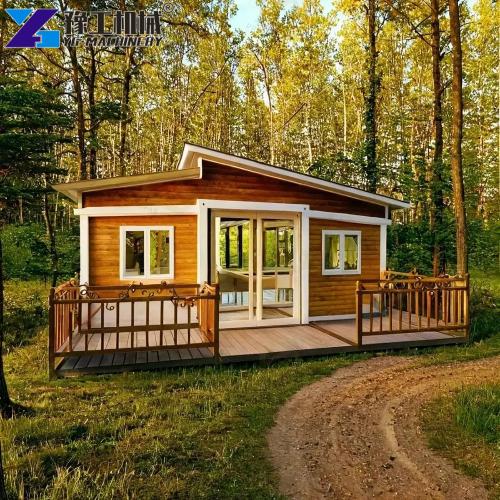

He searched for alternatives, compared prefabricated houses and modular huts, and finally focused on the YG 40ft expandable container house USA. “I needed houses that are ‘fast, cost-saving, and reliable’, and this product seemed to fit perfectly—later results proved it was even better than I expected,” Mike mentioned in his follow-up feedback.

40ft Expandable Container House USA Parameter:

| 20FT Basic Characteristics | External dimension (mm) | W6320*L5900*H2480(Side 2270) |

| Internal dimension (mm) | W6160*L5560*H2240(Side 2150) | |

| Folded state (mm) | W2200*L5900*H2480 | |

| Total mass (kg) | 2500 | |

| 30FT Basic Characteristics | External dimension (mm) | W6360*L9000*H2480(Side 2180) |

| Internal dimension (mm) | W6200*L8660*H2240(Side 2060) | |

| Folded state (mm) | W2200*L9000*H2480 | |

| Total mass (kg) | 3750 | |

| 40FT Basic Characteristics | External dimension (mm) | W6240*L11800*H2480(Side2180) |

| Internal dimension (mm) | W6080*L11540*H2200(Side2060) | |

| Folded state (mm) | W2200*L11800*H2480 | |

| Total mass (kg) | 4400 | |

| Smaller Fold Size | External dimension (mm) | W4820*L5900*H2480(Side2270) |

| Internal dimension (mm) | W4660*L5560*H2240(Side2150) | |

| Folded state (mm) | W700*L5900*H2480 | |

| Total mass (kg) | 1850 |

Why Choose YG 40ft Expandable Container House USA?

Mike didn’t choose the product randomly. After comparing 3 suppliers, he finally decided on YG’s 40ft expandable container house USA. There are 3 core reasons, which may also address your concerns:

1. Prefabricated Design: Meets Your “Tight Schedule” Needs

95% of 40ft expandable container house USA is assembled at YG’s factory, including water/electric pipelines, insulation layers, and basic interiors. After being shipped to Mike’s resort, 4 workers installed 20 units in 4 days—cutting construction time by 80% compared to traditional wooden houses, just in time for the summer peak season opening.

“I thought I’d miss the peak season, but we started trial operations a month early—this alone made an extra $120,000,” Mike said. Moreover, this product can be used with 20ft expandable container house; he later added 5 small units in the resort corner as staff dormitories, making space use more flexible.

2. Strong Weather Resistance: Adapts to Multiple US Regions

California’s mountains have heavy rain in summer and frost in winter, so Mike worried ordinary houses couldn’t withstand it. But 40ft expandable container house USA passed testing: it resists 120km/h strong winds (common in California’s rainstorms) and has an insulation layer with a thermal conductivity as low as 0.03W/(m·K). No extra heating is needed in winter, saving over $200 per room in monthly electricity bills.

YG’s pre-sales team also adjusted the foundation design for free based on the resort’s mountain terrain—this surprised Mike: “I didn’t expect the supplier to proactively consider site details, saving me the trouble of hiring a local design institute.”

3. Factory Direct Pricing: Cut Out Middleman Costs

Traditional construction involves multiple markups from “material suppliers – contractors – construction teams”, but 40ft expandable container house USA is directly supplied to the US by YG’s factory, with no middlemen. Mike calculated: the total cost of 20 units was 32% lower than traditional wooden houses, just bringing the over-budget back on track.

Moreover, transportation is hassle-free—the product can be directly loaded into US-standard 40HQ containers. From YG’s factory to California ports and then to the resort, a dedicated team tracks the entire process with no delays.

Mike’s True Feedback After 6 Months of Use

By early 2024, Mike had used 40ft expandable container house USA for 6 months, and his feedback was all “beyond expectations”:

- Occupancy rate: The 20 new guest rooms had a 92% occupancy rate in summer, 15% higher than the original wooden houses—guests said “the rooms have good views, no odors, and are more comfortable than traditional homestays”.

- Operating costs: Average monthly water, electricity, and maintenance costs per room are 28% lower than wooden houses.

- Flexibility: Last winter, he temporarily converted 3 units into ski equipment storage rooms, then restored them to guest rooms when not in use—no space wasted.

“If I expand again, I’ll still choose 40ft expandable container house USA—I even plan to replace some old wooden houses with it,” Mike also recommended it to a friend running a camp in Utah, who ordered 15 units.

Global Market Recognition of Expandable Container House

In fact, 40ft expandable container house USA is not just a choice for US customers—YG’s product has been sold to over 20 countries including Canada, France, Australia, Mexico, Spain, Malaysia, New Zealand, and Portugal:

- In Canada, customers use it as mining dormitories, resisting -10℃ low temperatures.

- On Australia’s coasts, it resists typhoons and becomes a “popular homestay style”.

- In Spain, many farmers use it as vacation cabins, matching container foldable house as warehouses for ultra-high cost-effectiveness.

Behind this is YG’s adaptation to different national standards: for example, the US version complies with UL certification, the European version meets CE requirements, and the Australian version passes AS/NZS testing—no matter which country you run a project in, you don’t have to worry about standard compliance.

Want to Copy Mike’s Success? 3 Steps to Get Your Exclusive 40ft Expandable Container House USA Plan

If you’re also troubled by accommodation construction for projects and want to “save time, cut costs, and ensure stable profits” like Mike, you can follow these 3 steps now:

- Contact YG customer service, specifying your project location and needs (guest rooms, dormitories, etc.);

- Get free 3D designs and quotes for expandable container house—you can also compare other models of expandable container homes for sale;

- After confirming the plan, YG will arrange production, transportation, and full remote installation guidance—no need for you to visit the factory.

Mike said: “Choosing the right product is half the success of a project.” And the YG expandable container house may be the “bonus” for your project.