In California, a construction project manager named David faced a difficult problem. His team was installing foundations for a coastal resort. The loud noise from their old pile driving method drew complaints from residents. Worse, the hard sandy soil slowed down work. The project fell far behind schedule. David urgently needed an efficient and quiet solution. He finally found a perfect vibratory pile driver.

How Did the YG Vibratory Pile Driver Solve Noise and Efficiency Issues?

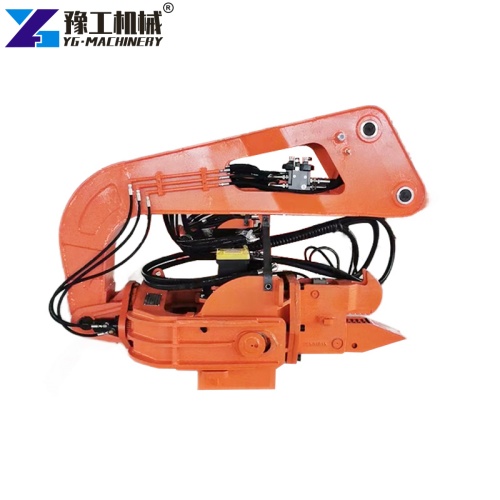

While searching for a solution, David found YG. He was very interested in YG’s vibratory pile driver. This product uses high-frequency vibration technology. It separates soil particles around the pile. This reduces friction. The method allows the pile to sink quickly and smoothly. Compared to traditional impact hammers, YG’s vibratory pile driver is much quieter. It was the perfect fit for the resort project’s environmental and low-noise needs.

Vibratory Pile Driver Parameter:

| Model | YG150D | YG250D | YG350D | YG400D | YG450D |

| Eccentric moment(kg*m) | 3.2 | 5.1/5.7 | 7.1 | 9.2 | 11 |

| Speed(rpm) | 2600 | 2600 | 2600 | 2600 | 2600 |

| Excitation force(t) | 24 | 38/42 | 52 | 68 | 81 |

| Operating pressure of oil system(bar) | 200 | 300 | 320 | 330 | 330 |

| Flow demand for hydraulic oil system(lpm) | 100 | 163 | 220 | 260 | 300 |

| Weight(t) | 1.2 | 1.6 | 2.4 | 2.5 | 2.6 |

| Excavator(t) | 8-12 | 20-25 | 25-35 | 35-45 | 40-55 |

Can a Vibratory Pile Driver Really Save Money?

David bought a YG vibratory pile driver. He quickly found it exceeded his expectations. It not only solved the noise problem but also boosted efficiency. Compared to his old method, YG’s vibratory pile driver made their piling speed 40% faster. This meant the project finished ahead of schedule. A shorter timeline directly cut labor costs and equipment rental fees. This return on investment made David very happy. The hydraulic pile driver for excavators proved its superior performance.

How Does Our Excavator Pile Driver Adapt to Different Projects?

On site, David’s team had to work with different types of piles. They used YG’s vibratory pile driver. It came with interchangeable clamps. This allowed them to easily install various sizes of sheet piles and steel pipes. This versatility meant the team did not have to switch equipment. It saved time and made their work more flexible. This excavator pile driver for sale earned high praise from David’s team for its strong adaptability.

Why Did YG’s Service Make the Client Feel Secure?

The choice of YG was not just about the product. David also valued the full service YG provided. Before the purchase, the YG expert team gave detailed technical advice and a customized plan. They helped David choose the right vibratory pile driver for his excavator. During use, YG’s remote technical support was always available. They ensured the equipment ran smoothly. This gave the client great peace of mind.

With its excellent performance and reliability, the YG vibratory pile driver has sold successfully in many countries. Our equipment is widely used in key projects in the USA, Canada, France, Australia, Mexico, Spain, and Malaysia. This vibratory hammer for excavator is helping global clients solve their construction problems. No matter where your project is, we can offer professional support and efficient solutions.

What is the Client’s Real Feedback on YG Products?

After the project, David was very pleased. He said: “YG’s vibratory pile driver completely changed how we work. It solved the noise problem and doubled our efficiency. The performance of this mini pile driver for sale is outstanding. YG’s service also made us feel very secure. I highly recommend YG’s products!” David’s success story proves the high quality and excellent performance of YG products. We look forward to partnering with more clients to achieve project success.

Contact us now to get a free quote. You can also learn about our customizable solutions. We also supply concrete pile breakers, scrap metal shear for excavators, hydraulic breaker hammers, hydraulic plate compactors, log grapple, car dismantling shear, excavator pile drivers, hydraulic magnet for excavator, hydraulic pulverizer, milling head for excavator, vehicle dismantler, hydraulic quick hitch, excavator rock saw, and other excavator attachments.