In the Midwest of the United States, a large-scale egg producer faced a critical bottleneck. Their outdated equipment was inefficient, often causing production line downtime. This not only increased operational costs but also impacted the timely delivery of their products. They urgently needed a highly efficient and reliable egg tray machine to solve these issues. After a thorough market search and evaluation of multiple suppliers, they ultimately turned to YG. They believed that choosing a YG egg crate making machine was the key to overcoming their challenges.

YG Egg Carton Making Machine Popular Models

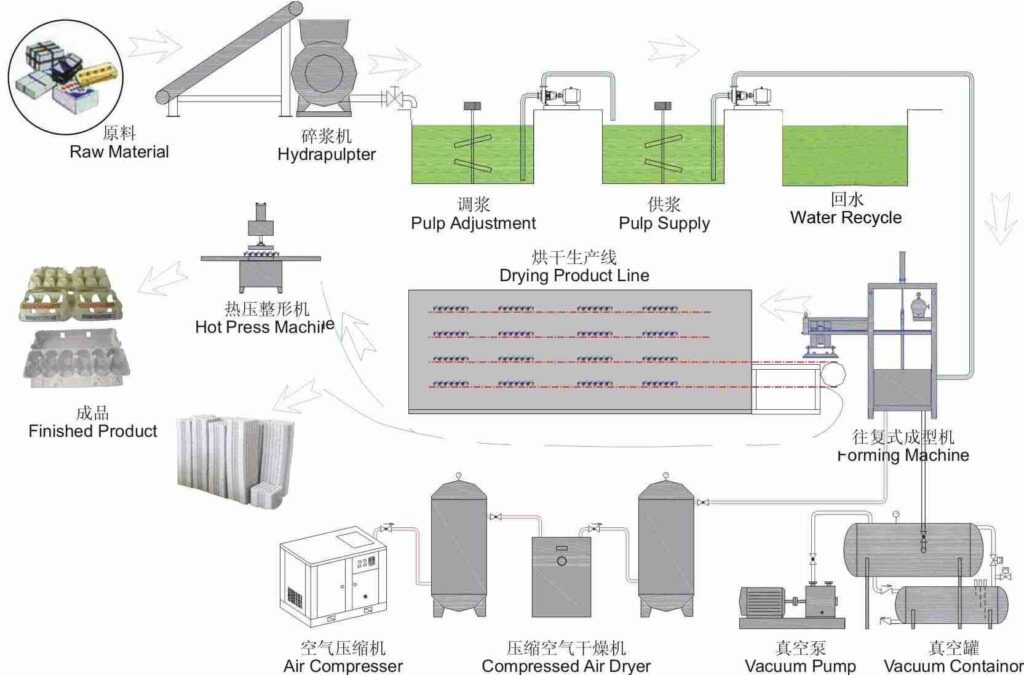

We have different egg tray production lines with different outputs and configurations according to the different needs of customers and budgets.

| Model | Output(pcs/h) | Mould Quantity | Total Power(kW) | Raw Materials (kg/h) |

| DT-1*3 | 1000 | 1*3+3 | 41 | 23.8 |

| DT-1*4 | 1500 | 1*4+4 | 41 | 28.4 |

| DT-3*4 | 2000 | 3*4+3 | 53.7 | 32.57 |

| DT-4*4 | 3000 | 4*4+4 | 57 | 39.9 |

| DT-4*8 | 4000 | 4*8+4 | 90 | 63 |

| DT-5*8 | 5000-6000 | 5*8+5 | 150 | 105 |

| DT-5*12 | 6000-7000 | 5*12+5 | 153 | 107.1 |

Client’s Pain Points and Needs: Why a New Egg Tray Making Machine?

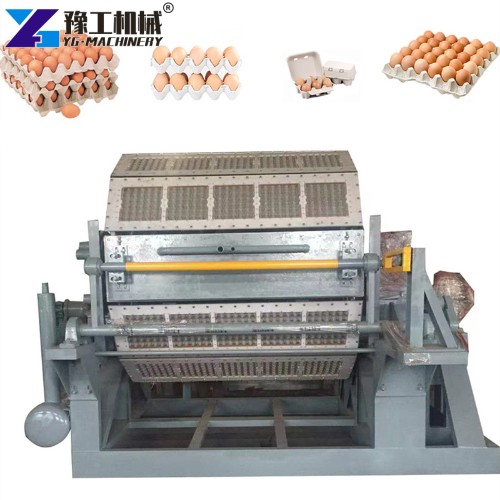

Our client, Mike, operates a large egg farm in the US. As his business rapidly expanded, the demand for egg trays grew exponentially. However, his existing egg carton machine was not only slow but also prone to frequent breakdowns. This led to his team constantly stopping for repairs, which significantly reduced production efficiency. Mike needed a new, more automated egg tray production machine. This machine had to be capable of stable, long-term operation and produce high-quality, structurally sound egg trays.

The Unique Advantages of the YG Solution

When searching for new equipment, Mike focused on more than just the machine itself. He valued a supplier’s complete solution and after-sales support. YG’s professional team provided him with a detailed consultation. We took the time to understand his production process and specific requirements. Ultimately, we recommended a fully automatic egg carton making machine. This machine utilizes advanced molding technology to ensure consistent shape and robust durability. Its energy-efficient design also perfectly met the client’s need to reduce operational costs.

Outstanding Results and ROI from the YG Egg Tray Making Machine

After installing and running the YG egg tray making machine, Mike quickly saw remarkable results. First, production efficiency significantly increased. The new equipment could produce tens of thousands of egg trays daily, boosting capacity by 40%. Second, due to the machine’s stable operation, downtime was virtually eliminated. This not only cut maintenance costs but also ensured a smooth supply chain. Mike was also highly satisfied with our service. From initial equipment selection to post-installation debugging, YG’s engineering team maintained a professional attitude. They provided detailed operational training and established a remote technical support system. Even across continents, we ensured the equipment ran smoothly.

YG’s Global Footprint

The YG success story isn’t limited to the United States. Our egg tray production machine has been successfully sold to many countries around the world. For instance, in Saudi Arabia, our egg tray machine helped a local client achieve efficient egg tray production. In South America, our equipment is also highly popular. In Peru and Colombia, our egg carton machine has helped local farms expand their businesses. These success stories are strong proof of the reliability of YG products. We are committed to providing global clients with high-quality egg box making machine solutions and exceptional service.

Return on Investment: The Long-Term Value of YG’s Egg Tray Making Machine

Mike stated that choosing the YG egg carton making machine was a wise investment. While there was an initial capital outlay, the high production efficiency and low operational costs quickly provided a return. He expects to fully recoup his investment within two years. Moreover, by producing high-quality egg trays, his products became more competitive in the market. This not only enhanced his brand image but also attracted more customers. Mike is confident about the future and plans to continue his partnership with YG.