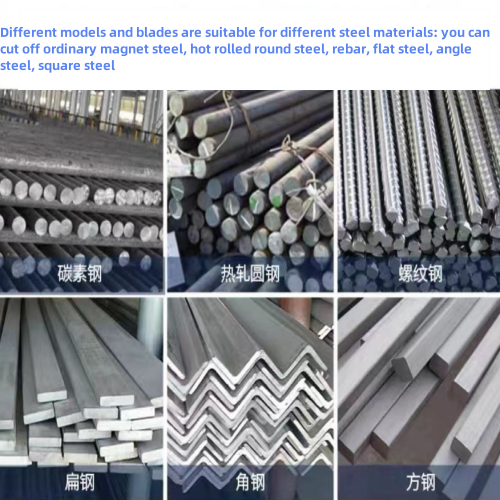

In Monterrey, Mexico, a construction contractor named Marco faced a big problem. His team was building a large residential complex. The project needed a huge amount of bent rebar. They had been relying on manual bending tools. This method was very time-consuming. It was also hard to ensure bending accuracy. The work was very physically demanding for the workers. These issues severely slowed down the project’s overall progress. They also increased labor costs. Marco urgently needed to find an efficient and precise steel bar bending machine. He needed a solution to quickly boost productivity.

YG’s Steel Bar Bending Machine: Precision Technology for the Project Needs

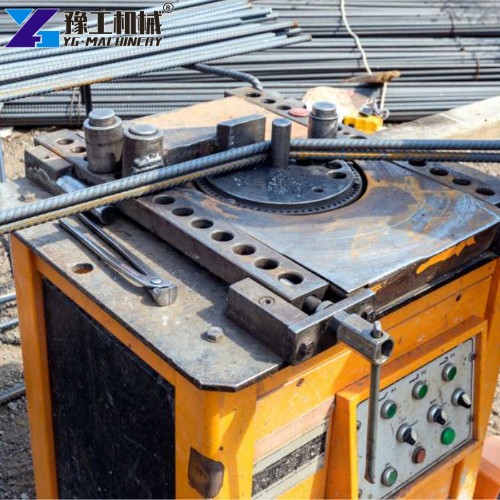

To solve these challenges, Marco started looking for new equipment suppliers. He needed a steel bar bending machine that could handle various rebar diameters. A friend recommended YG Machinery, so he reached out to us. The YG sales team responded quickly. They carefully understood Marco’s project scope and rebar specifications. The YG team recommended a rebar bending machine designed for large-scale construction projects. This machine is easy to operate, fast, and highly accurate. It can easily bend rebar up to 32mm in diameter. This was a perfect match for Marco’s construction needs. YG’s solution gave him hope for speeding up his project.

Parameter of Steel Bar Bending Machine:

| Model | YG-26 | YG-38 | YG-51 | YG-76 | YG-N76 |

| Tube diameterMaximum wall thickness | Φ8-26mm2mm | Φ10-38mm3mm | Φ10-51mm3mm | Φ10-76mm3mm | Φ10-76mm4-5mm |

| Maximum square tube diameterMaximum wall thickness | 25mm2mm | 30mm3mm | 40mm3mm | 50mm3mm | 60mm3mm |

| Maximum rectangular tube diameter(Vertical Bend) Maximum wall thickness | 10*20mm2mm | 20*40mm3mm | 30*50mm3mm | 40*80mm3mm | 50*100mm3mm |

| Maximum rectangular tube diameter(Flat bend)Maximum wall thickness | 10*20mm2mm | 20*30mm3mm | 20*40mm3mm | 30*50mm3mm | 40*80mm3mm |

Why YG Was the Right Choice: Excellent Performance and Worry-Free Service

Why did Marco choose YG Machinery in the end? Besides the product’s great performance, YG’s comprehensive service was key. YG’s steel bar bending machine uses advanced CNC technology to ensure precise control of bending angles and repeatability—directly solving the accuracy problems Marco faced before. The YG team also provided detailed pre-sales consultation, a tailored return on investment analysis based on his needs, as well as remote installation guidance and operation training. This thoughtful service gave Marco great confidence, knowing he was not just buying a machine but gaining a reliable partner.

Remarkable Results: Double the Productivity, Major Cost Savings

After implementing YG’s steel bar bending machine, Marco’s project made amazing progress. The rebar bending work that used to take a month was now done in just two weeks. Productivity doubled. Because of the machine’s precise bending, the scrap rate was almost zero. This saved Marco a lot of money on materials and labor. Marco said excitedly, “YG’s rebar bending machine was key to our project’s success in Mexico. It greatly increased our work efficiency and guaranteed construction quality. We are very grateful for the YG team’s professional support.” The return on investment for this purchase was very high, far exceeding expectations.

Huge Market Potential in Mexico: A Bright Future for YG Steel Bar Bending Machine

Mexico’s construction market is booming, especially in infrastructure and residential building. This creates a huge market demand for the steel bar bending machine. Efficient and precise automated equipment is becoming the main trend. YG’s steel bar bending machine has earned a good reputation in the Mexican market because of its excellent performance and competitive pricing. The machine’s high cost-effectiveness gives YG products a strong competitive edge in the Mexican market. YG plans to continue investing in the Mexican market to provide more clients with high-quality construction machinery.

After-Sales Support For Steel Bar Bending Machine

To help customers, YG Machinery provides:

- One-year warranty on main parts

- Fast shipping for spare parts

- Online video support and guides

- Clear user manuals in English

- Technical advice for machine settings

These services keep your projects running smoothly.

YG Machinery has focused on rebar processing equipment for 15 years, with products exported to 60+ countries, including Indonesia, Nigeria, and Brazil. Whether you need a single steel bar bending machine or a complete automated line (including automatic stirrup bending machine and bar straightening machine), we can tailor solutions to your needs. Contact us today for a free technical plan and quotation! 【WhatsApp/WeChat/Phone】+86 138 3711 2713