In Germany, the construction industry demands rigorous efficiency and precision. Mr. Müller, a prominent precast concrete component manufacturer in Frankfurt, faced a pressing issue. He needed an effective way to process a large volume of bent rebar. Their old equipment was inefficient, increasing labor costs and extending project timelines. Mr. Müller realized they urgently needed a high-performance steel bar straightening machine to optimize their production process.

Precise Application: How YG’s Steel Bar Straightening Machine Transformed a German Project

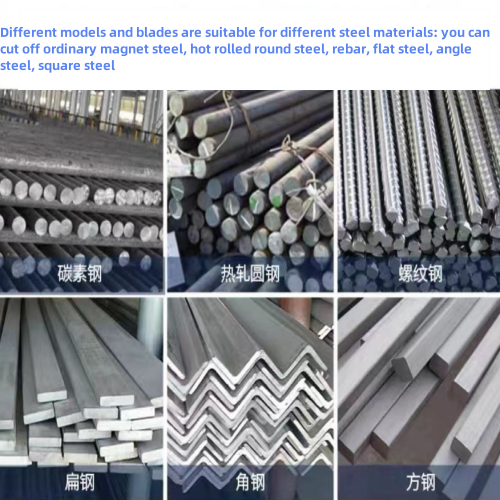

Mr. Müller’s company took on a significant infrastructure project. This project required a large quantity of precisely sized straight rebar. Facing increasing orders and strict rebar quality requirements, their existing rebar processing methods were insufficient. They envisioned integrating an advanced rebar straightener for fast, precise rebar straightening and cutting. YG Machinery’s steel bar straightening machine perfectly met their needs, offering an ideal solution. It can handle rebar of various diameters, ensuring every bar meets high standards.

Technical Parameters of Steel Bar Straightening Machine

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire Length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

YG Solution’s Unique Advantages: The Reliable Bar Straightening Machine

- Product Quality and Performance: Our steel bar straightening machine features an intelligent PLC control system, ensuring unparalleled straightening accuracy and cutting efficiency. The equipment is designed with double-curve inclined rollers and alloy straightening wheels, minimising rebar wear. This directly resolved Mr Müller’s long-standing issues with rebar scratching and strength loss. The hydraulic cutting system eliminates continuous cutting, significantly reducing material waste. Furthermore, it easily processes rebar across a wide diameter range.

- Service Support: From the initial consultation, YG’s team demonstrated high professionalism. We provided detailed customised solutions, ensuring the rebar straightener machine perfectly matched Mr Müller’s production requirements. During equipment installation and commissioning, our technicians offered timely on-site guidance. Afterwards, comprehensive remote technical support and ample spare parts supply gave Mr Müller confidence in the machine’s long-term operation. This all-encompassing service guarantee was a key factor in their decision to choose YG.

Remarkable Outcomes: The German Client’s Bar Straightening Machine ROI

Since the deployment of YG’s steel bar straightening machine, Mr. Müller’s company has seen a significant boost in production efficiency. They reported a 40% increase in rebar processing speed and a 25% reduction in scrap rates. This translates to substantial cuts in production costs, with projects now completed on time or even ahead of schedule. Mr. Müller praised, “YG’s bar straightener machine is the smartest investment we’ve made. It not only boosted our capacity but also delivered a remarkable return on investment, exceeding our expectations. The YG team’s service was also impeccable.” This equipment helped them secure more crucial contracts, solidifying their market position.

Market Insight: Growing Demand for Bar Straightener Machine in Germany

The German construction market’s demand for high-quality, high-efficiency steel bar straightening machine continues to grow. With ongoing infrastructure development and urban renewal projects, the need for rebar processing equipment with high precision and stable operation is increasing. YG Machinery’s steel bar straightening machine, with its reliable performance and excellent cost-effectiveness, demonstrates strong competitiveness in the German market. Our success story proves that YG’s products effectively meet German clients’ expectations for advanced rebar processing equipment, further enhancing our reputation and influence in the global market.