In the United States, a farmer named Michael faced a big problem: too much silt in his farm’s irrigation ditches. This affected irrigation and worsened water quality. He needed an effective way to clear the silt, but traditional manual cleaning was both time-consuming and dangerous. Michael heard about a smart device called a silt removal machine. He found YG company. YG provided him with a silt removal machine, and Michael was very satisfied. He felt YG’s service was thorough, and the product quality was excellent.

Sludge Cleaning Robot Parameter:

| Dimension: | 1220*890*520mm | Speed: | 2.5-4KM/h |

| Self Weight: | 120kg | Designed Load: | 100-300kg |

| Waterproof: | IP68 | Rated Torque: | 100-500 NM |

| Track Width: | 130mm | Reducer Efficiency: | 65-85% |

| Gear Ratio: | 1:10-1:40 | Motor Voltage: | 380ACV (customized as local voltage) |

| Motor: | 0.75-1.5KW*2 | Climbing Ability: | ≤30°(can climb stairs) |

| Motor Rated Speed: | 1500r/min | Maximum Span: | 620mm |

| Cable Control Distance: | Standard 50m, maximum 150m | Over-Obstacle Capacity: | 130mm |

| Maximum Underwater Depth: | 30m | Power Supply: | Generator or 380V power supply |

Current Market Situation in the US

In the United States, the demand for silt removal machine is growing. Many cities, industrial enterprises, and farms need to clear pipes, rivers, and ditches. Traditional manual cleaning methods carry significant risks, especially in toxic or confined environments. Therefore, more clients are looking for intelligent solutions like the silt removal machine. This silt removal machine can not only replace manual labor in high-risk environments but also improve work efficiency. The market demand for dredging robot and sludge cleaning robot is also continuously increasing.

Features and Advantages of the Silt Removal Machine

First, it can replace manual labor in high-risk environments. This means workers don’t need to enter dangerous pipes or underwater settings, significantly enhancing operational safety. Second, its work efficiency is very high, capable of processing 100 to 300 cubic meters of silt per hour, which is much faster than manual methods. Furthermore, it reduces secondary environmental damage, making it an eco-friendly cleaning method. This silt removal machine can adapt to various complex scenarios, such as wastewater treatment tanks in chemical plants or narrow urban pipelines. It can clear various locations like pipes, rivers, and ditches, meeting diverse needs.

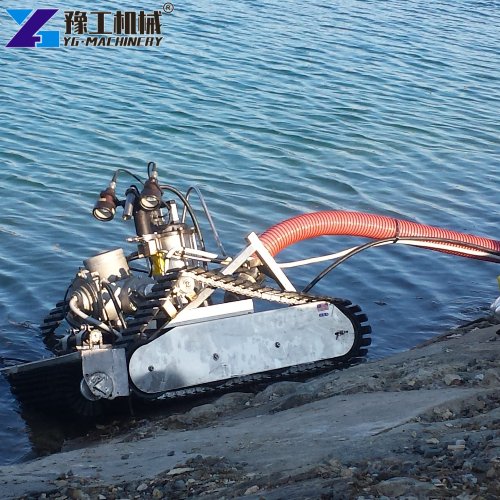

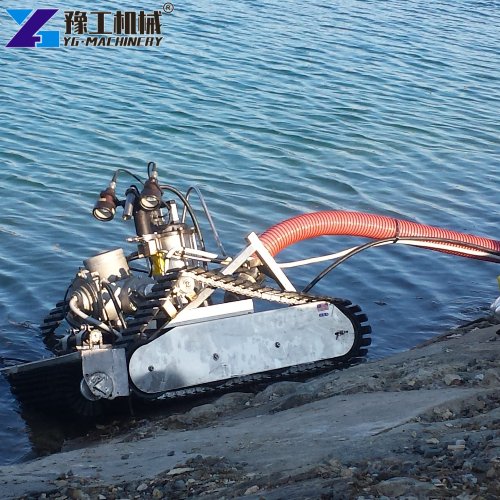

How the Silt Removal Machine Works

The working principle of the silt removal machine is quite interesting. It mainly consists of several parts: a hydraulic pump station (providing power), the robot body, oil pipes, and sewage pipes. The robot itself has “eyes” and a “brain.” Its “eyes” are sensors, such as LiDAR, visual cameras, and ultrasonic sensors, which help it perceive its surroundings and avoid obstacles. Its “legs” are the drive mechanisms, which can be wheels, tracks (for pipes), or propellers (for water bodies), allowing it to move in different environments. The “hands” for clearing silt include a high-pressure water jet device (to flush silt), a robotic arm or cutter (to break up large silt clumps or grasp debris), and a suction system that draws silt and wastewater into a storage tank for centralized disposal. All these operations can be done through remote control, allowing operators to monitor the robot’s work from a safe distance.

Why Did the Client Choose YG?

Michael chose YG for a simple reason. He learned that YG’s silt removal machine has successful applications in industrial wastewater treatment, urban river dredging, and aquaculture. For example, after a chemical plant introduced YG’s sludge cleaning robot, their cleaning cycle significantly shortened, reducing maintenance costs. In an urban river dredging project, YG’s small dredging machine completed a task in just one month that previously took three months. These cases demonstrate the excellent performance of YG’s silt removal machine and YG’s commitment to providing quality service.