Choosing a good block brick making machine is important. It’s like picking the right helper. The right machine can save you money and produce high-quality bricks. This guide will help you understand different types of block brick making machines.

Brick Machine Production Capacity:

| Block Name | Size (L*W*H)mm | Molding Cycle | QTY/Mould | QTY/hour | Qty/8hr |

| Hollow block | 400*200*200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520pcs |

| Hollow block | 400*150*200 | 15-20s | 7pcs | 1260-1680pcs | 10080-13440pcs |

| Hollow block | 400*100*200 | 15-20s | 11pcs | 1980-3640pcs | 15840-21120pcs |

| Porous block | 240*115*90 | 15-20s | 15pcs | 2700-3600pcs | 21600-28800pcs |

| Standard brick | 240*115*53 | 15-17s | 30pcs | 6300-7200pcs | 50400-57600pcs |

| Paver | 225*112.5*60 | 20-25s | 15pcs | 2160-2700pcs | 17280-21600pcs |

A block brick making machine is a special kind of machine. It uses many different things to make bricks. For example, slag, mine waste, fly ash, sand, and cement. These materials are processed by the machine and become strong cement bricks, hollow blocks, or colored paving bricks. These bricks don’t need to be fired; they can be used after drying. So it’s also called a non-fired brick machine.

Choosing Your Block Brick Making Machine

- What is your budget?

- What raw materials do you plan to use to make bricks?

- Do you want the machine to be fully automatic or semi-automatic?

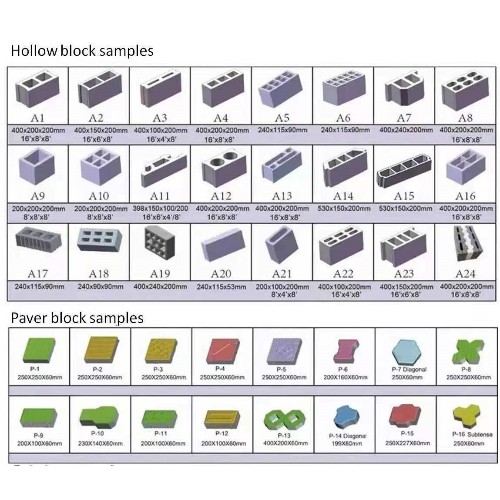

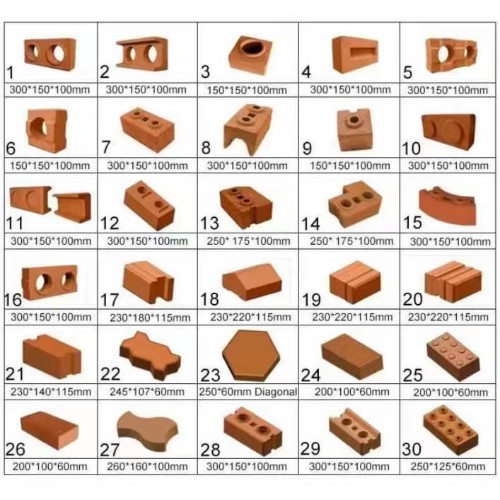

- What type of bricks do you want to produce, such as hollow bricks or colored bricks? paving block or curbstone?

- Brick size?

- Daily production (8 hours)?

Features of a Block Brick Making Machine

A good block brick making machine has many advantages. It can use waste materials like slag and fly ash to make bricks. This is environmentally friendly and reduces waste. The bricks it produces are very strong. These bricks can be used in houses, roads, and other places. The machine can also customize bricks of different shapes and sizes. This makes your products more diverse.

Working Principle of a Block Brick Making Machine

The working principle of a block brick making machine is interesting. The main motor drives the belt to rotate. The belt connects to the reducer. The reducer makes the small gear rotate. The small gear then drives the large gear to rotate. In this way, the beam inside the machine will move up and down. When the beam moves up and down, it feeds raw materials into the mold and pushes out the finished bricks. The pressing system will repeat this process: feeding, pressing, ejecting, pushing out, and then feeding again. The entire process is very smooth, like a cycle.

Forming Methods of a Block Brick Making Machine

There are three main forming methods for a block brick making machine. The first is vibration forming. It compacts raw materials by vibrating. The second is hydraulic forming, which uses great force to press raw materials into bricks. The third is a combination of hydraulic and vibration, which combines the advantages of the first two. Different forming methods will affect the hollow brick making machine price and the machine’s performance. The choice of method depends on the type of bricks you want to produce and your budget.

Automatic vs. Semi-Automatic Brick Machine

Block brick making machines are also divided into automatic and semi-automatic types. An automatic brick machine has high efficiency. It can complete most of the work by itself, reducing manual labor. This is very beneficial for large-scale production. Semi-automatic machines require more manual operation, but the cost may be lower. Depending on your production needs and budget, you can choose the most suitable type of block brick making machine for you.

Different Raw Materials for Brick Machine

Block brick making machines can also be classified based on the raw materials used. For example, there are vacuum extrusion brick machines, usually used for clay bricks. There are also clay brick machines, specifically for making clay bricks. In addition, cement brick machines use cement as the main raw material. Your raw material type will determine which brick machine you need.

If you still have questions about specific machine types welcome to contact YG for more product details and quotes!【WhatsApp/WeChat/Phone】+86 138 3711 2713