The construction industry in Portugal is growing. So there is a great demand for bricks. Especially, high-quality and low-cost non-fired bricks are needed. YG brick and block machine perfectly meets these needs. There is strong market interest in efficient and environmentally friendly production equipment. This includes attention to the hollow bricks machine price.

The construction industry in Portugal is growing. So there is a great demand for bricks. Especially, high-quality and low-cost non-fired bricks are needed. YG brick and block machine perfectly meets these needs. There is strong market interest in efficient and environmentally friendly production equipment. This includes attention to the hollow bricks machine price.

Brick And Block Machine Production Capacity:

| Block Name | Size (L*W*H)mm | Molding Cycle | QTY/Mould | QTY/hour | Qty/8hr |

| Hollow block | 400*200*200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520pcs |

| Hollow block | 400*150*200 | 15-20s | 7pcs | 1260-1680pcs | 10080-13440pcs |

| Hollow block | 400*100*200 | 15-20s | 11pcs | 1980-3640pcs | 15840-21120pcs |

| Porous block | 240*115*90 | 15-20s | 15pcs | 2700-3600pcs | 21600-28800pcs |

| Standard brick | 240*115*53 | 15-17s | 30pcs | 6300-7200pcs | 50400-57600pcs |

| Paver | 225*112.5*60 | 20-25s | 15pcs | 2160-2700pcs | 17280-21600pcs |

Customer’s Purchase Background

Mr. Pedro is a builder in Portugal. He needed an efficient way to produce building materials and wanted to reduce production costs, and also wanted to produce environmentally friendly bricks. He learned that our brick and block machine does not require firing. This was perfect for his project. He is building a large residential area. He had high expectations for our brick and block machine.

Features and Advantages of the Brick Making Machine

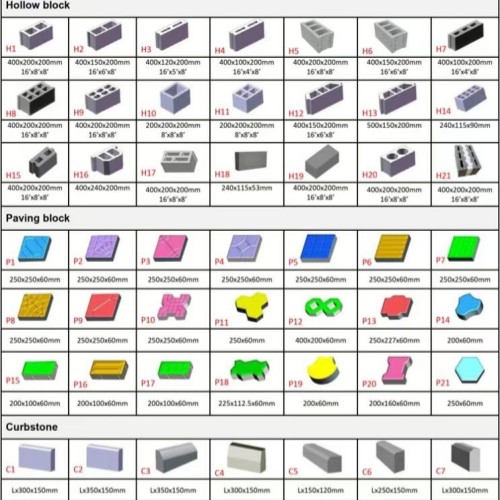

YG brick and block machine has many advantages. It uses various waste materials like slag, mine waste, and fly ash as raw materials. This is very environmentally friendly. It does not require firing. This saves energy. The produced cement bricks, hollow blocks, and colored paving bricks are of high quality. They are very strong and durable. The machine has high production efficiency. It can also customize various brick models. This hydraulic brick making machine is very efficient.

Working Principle of the Brick And Block Machine

The working principle of the brick and block machine is simple. The main motor drives a reducer via a belt. The reducer drives gears to rotate. The gears then drive the main shaft to rotate. The main shaft’s movement makes the beam move up and down. The beam’s movement simultaneously completes feeding and pushing bricks. When the beam lifts, the pressed bricks are pushed out of the mold. At the same time, the material cart delivers new material to the mold. This entire process cycles repeatedly. Machines are classified into three types based on their forming principle: vibration forming, hydraulic forming, and a combination of hydraulic and vibration. They are also divided into automatic and semi-automatic types.

Why the Customer Chose YG?

Mr. Pedro chose YG for several reasons. First, we provide high-quality brick and block machine. Second, our service is very comprehensive. We explained the machine’s advantages in detail. We also offered after-sales support. He also compared the clay brick making machine price with other machines. He found our product to be very cost-effective. YG answered all his questions. He believed that YG’s brick and block machine would help his project succeed.

Customer Feedback

Mr. Pedro is very satisfied with YG brick machine. He said the machine runs stably. The bricks produced are of excellent quality. He thanked us for our comprehensive service and technical support. Our cooperation was very successful. He stated that he would recommend YG brick and block machine to others. This successful cooperation proves the reliability of YG products.

“YG gave fair hollow bricks machine price. Now I make 3x more bricks!”

— Mr. Pedro

If you are interested in brick making machines, you can contact us at any time to get more product knowledge and information, as well as quotations. Of course, customization is supported.