As an economic hub in the Middle East, Saudi Arabia has been vigorously promoting economic diversification, with waste paper recycling and environmentally friendly packaging industries emerging as key growth areas. Stricter government policies limiting plastic use have driven a sustained increase in demand for degradable pulp egg trays. Industry data shows that waste paper accounts for 7% of Saudi Arabia’s municipal solid waste annually, with rising recycling rates providing abundant raw materials for egg tray production machine. Current market demand focuses on egg packaging, fruit transportation, and coffee cup holders, growing at an annual rate exceeding 12% and attracting global equipment suppliers.

Core Features and Technical Advantages of Egg Tray Production Machine

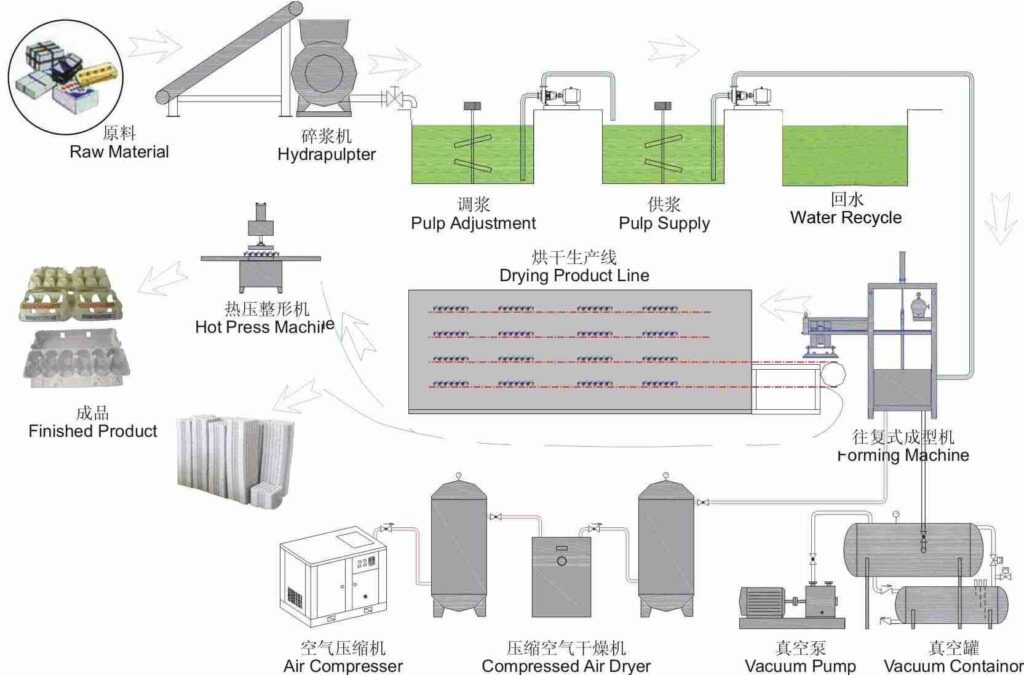

Egg tray production machine utilizes pulp molding technology, achieving efficient production through three key stages: pulping, forming, and drying. Their core advantages include:

- Multi-Functional Mold Design: Capable of producing 24/30-cell egg trays, 6/12-cell egg cartons (egg carton making machine), and fruit trays, adapting to diverse market needs.

- Energy-Efficient Drying System: Multi-layer metal drying lines (18m×6 layers) using natural gas or diesel reduce energy consumption by 30% compared to traditional tunnel drying, processing 7,000 trays per hour.

- Automated Control: Equipped with internationally renowned electrical components, enabling precise monitoring of pulp concentration and vacuum adsorption to minimize manual intervention.

- Environmental Certification: Holding international certifications, their closed-loop water systems recycle over 90% of wastewater, complying with Saudi Arabia’s green industrial standards.

Successful Application of Egg Tray Production Machine in Saudi Arabia

Customer Background: A local Saudi food packaging enterprise supplying egg packaging to domestic supermarkets and export markets. The original production line relied on traditional sun drying, suffering from low efficiency and weather dependency, leading to 15-day order lead times that failed to meet peak-season demands.

Solution:

In 2024, the enterprise adopted a fully automatic drum-type egg tray production machine with a multi-layer metal drying line. The equipment produces 7,000 trays per hour—tripling original capacity—and supports custom 12-cell egg carton molds for export to European and American markets.

Performance Feedback:

- Efficiency Boost: Full production cycle from waste paper to finished trays is shortened to 30 minutes, reducing order lead times to 5 days and increasing peak-season output to 160,000 trays daily.

- Cost Optimization: Natural gas consumption of 40–50 m³/h cuts drying costs by 25%, saving approximately $180,000 annually in fuel expenses.

- Quality Assurance: Aluminum molds with a 5-year lifespan enhance tray compressive strength by 20%, lowering breakage rates from 5% to under 1%.

The enterprise’s technical director stated, “The new egg tray production machine not only resolved our capacity bottleneck but also significantly reduced labor costs through its intelligent control system. The reliability of our equipment and the quality of our after-sales service have really boosted our competitiveness in the Saudi market.

Key Factors in Customer Selection

- Customization Services: Suppliers tailored electrical components and stainless-steel chimneys to Saudi customers’ needs, guiding local procurement of auxiliary parts to reduce shipping costs.

- End-to-End Support: From production to installation, technical teams ensured smooth project delivery via real-time video support. Quarterly after-sales visits provide mold maintenance and technical upgrades.

- This egg tray production machine model is 15% more affordable than competitors. Moreover, it boasts a significant energy cost advantage, ensuring an investment payback period of just 18 months.

With Saudi Arabia’s continued investment in environmental industries under Vision 2030, the egg tray production machine market faces substantial opportunities. Efficient energy-saving equipment, flexible customization, and localized services are becoming core criteria for Saudi customers when choosing partners. To learn about egg tray making machine price or request a free solution, contact us now.